modernization

News Companies capital investment

05 August 2022

The plant's specialists conducted an experiment to obtain the required characteristics of pellets by processing them with special substances

News Companies capital investment

01 August 2022

The new unit has a high throughput and productivity, which significantly reduces energy costs

News Companies capital investment

28 July 2022

Due to this, the use of natural gas in candle lighters was reduced by 40 m3/h

News Companies capital investment

25 July 2022

The plant repaired the mill of technological section No. 8

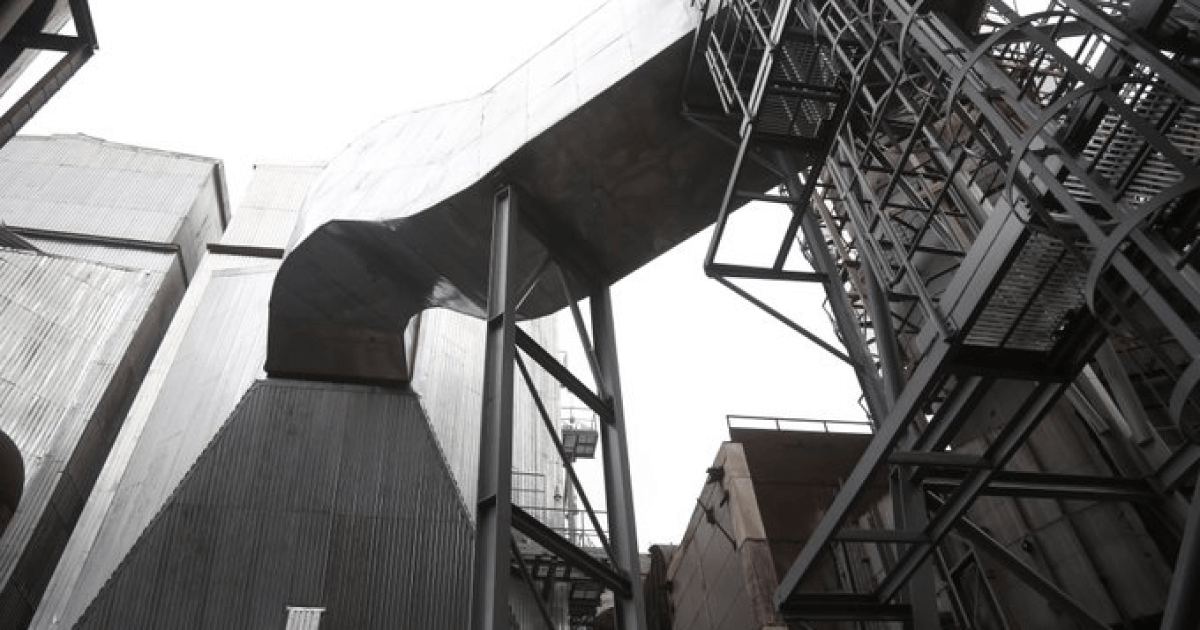

News Companies Zaporizhzhia Coke Plant

07 June 2022

Equipment modernization started in December 2021, but was paused during hot conservation in March

Posts Industry capital investment

10 August 2020

In 2020, investment of mining & metals companies may reduce by a third against last year