News Companies capital investment 1523 05 August 2022

The plant's specialists conducted an experiment to obtain the required characteristics of pellets by processing them with special substances

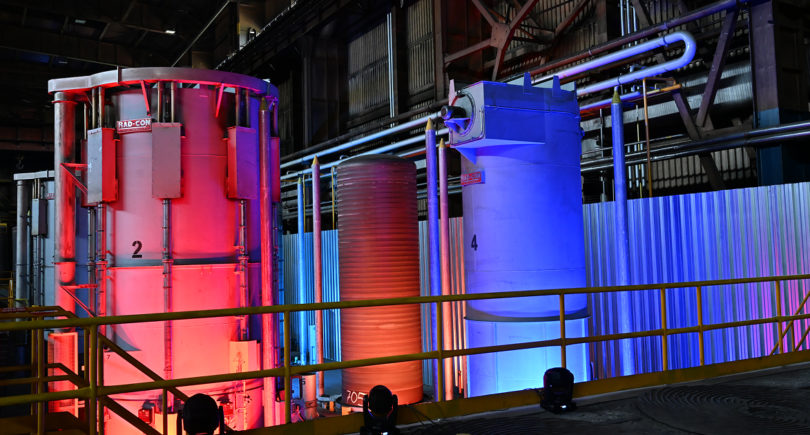

At the Central Mining and Processing Plant (Central GOK), the Metinvest group conducted research and industrial tests on the coating of pellets which is used in the Direct reduced iron (DRI) technology. Corporate edition of Metinvest Media reports about it.

“Specialists of Central Mining conducted an experiment to obtain the necessary quality characteristics of pellets by processing them with special substances. The first batch of new products has already been shipped. Thanks to the experiment, steel companies – recipients of Central GOK products – will be able to improve technological processes in the production of iron,” the message says.

Preliminary test results give hope that protection from agglomeration during direct recovery will be higher than competitors’. Thus, thanks to the new technology, Metinvest not only remains a stable player on the market, but also gives a positive signal for further development and separation from competitors.

In July, the Central Mining and Processing Plant repaired mill of technological section No. 8. Armor on the drum, scoops, nozzles of the loader and the body of the feeder were replaced.

As GMK Center reported earlier, in 2021 Central GOK shortened production of iron ore concentrate by 2.1% compared to 2020 – up to 4.8 million tons. Production of pellets decreased by 0.5% – up to 2.26 million tons.

Central GOK is among the five largest producers of iron ore in Ukraine. It specializes in mining and production of concentrate with iron content of 68.5% and 70.5%, as well as pellets with iron content of 67.5%.