Opinions Green steel decarbonization 419 19 February 2020

Funding of decarbonization remains the key problem affecting the industry

The defined CO2 reduction target of 80% can only be met by the full commitment of the global industrial community involving all CO2-emitting sectors. It is evident that the target can only be met by a consorted and holistic approach of the world community and would need a rather long transition period.

Horst Wiesinger Consulting with their senior experts consider this topic as one of the top priority development of the steel industry in the coming decades. HWC was already involved in several projects and would be pleased to support the individual companies in this issue.

Half a century under pressure

Over the past 50 years, the steel industry has been under pressure of environmental challenges. At first, concerns were raised over visible pollution (smoke, dust). This could be seen on the example of the first official air pollution control regulation, Technical Instructions on Air Quality Control, adopted in Germany in 1964. These instructions set emission limits for dust, sulfur dioxide, nitrogen oxides and other compounds. Although the document was binding in Germany only, many European countries decided to follow its recommendations.

Public interest in environmental issues substantially increased following accidents at chemical plants. In July 1976, an industrial accident at a chemical plant near Seveso, Italy, resulted in a release of dioxin. In December 1984, an accident at a chemicals plant in Bhopal, India, released poisonous gases, killing 3 thousand people.

European regulations

Following these events, the European Commission started to collect environmental data on industrial production. It resulted in the adoption in 1996 of Council Directive concerning integrated pollution prevention and control. Directive 2008/1/EC of 2008 substantially amended the previous document. The main idea of the document is that the emission permit is granted only if a plant complies with the ‘best available techniques.’ The ‘best available techniques’ are described for all sectors, including steel production.

The ‘best available techniques’ lack requirements for СО2 emissions, which are becoming increasingly important. In 2015, the Paris Agreement on Climate Change was signed. However two years later, in 2017, the USA left this agreement. The parties agreed to keep the increase in global average temperature to well below 2°C above pre-industrial levels and to pursue efforts to limit the increase to 1.5°C.

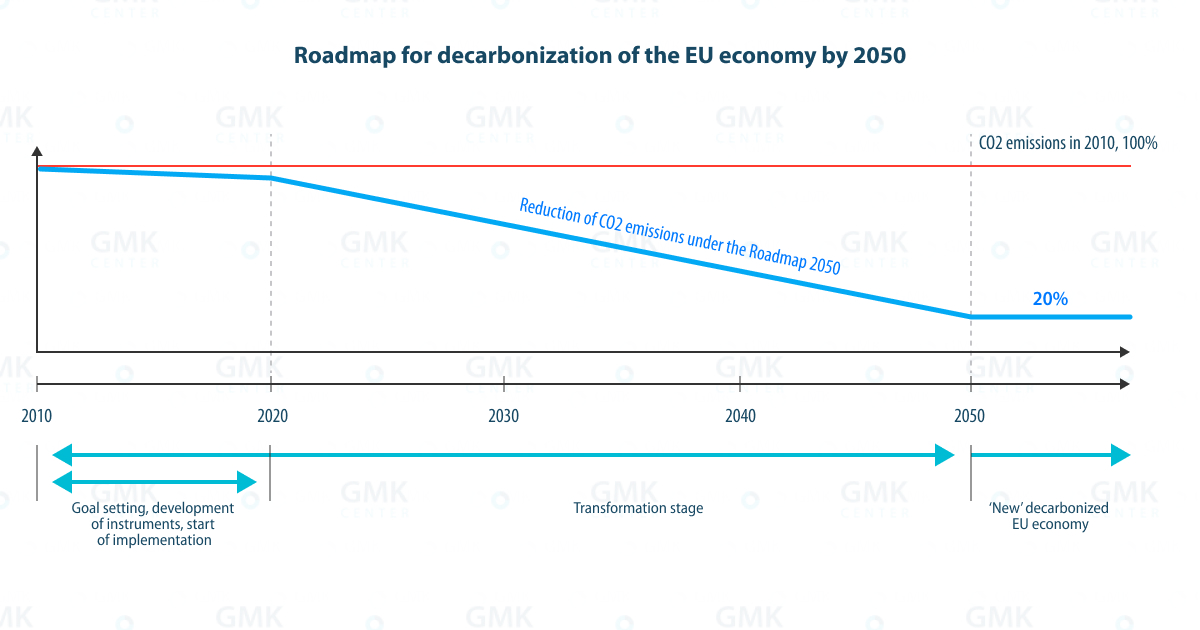

The EU is moving towards the carbon-free economy in the framework of the Paris Agreement. A discussion of possible goals and tools of the reduction of СО2 emissions is expected to end in 2020 so as to start a transition. The discussion’s effectiveness is proved by the conclusion of the European Green Deal. It is a strategy for the EU to achieve a climate-neutral economy by 2050.

Prospects for the implementation

This ambitious goal could be achieved only in interaction of governments and plants. Carbon-free technologies, represented mainly by individual solutions and research projects, are at a fledgling stage. In the steel industry, the first wave of cutting-edge technologies on an industrial scale could be expected after 2035 at the earliest.

Funding of decarbonization remains the key problem affecting the industry. For steelmaking companies, decarbonization primarily means a growth in capital investment. The EU is ready to partially compensate for these costs as part of the European Green Deal, realizing that it is impossible to implement such global project without government support. It is also apparent that decarbonization will increase the cost of production and, as a result, cause a loss of competitiveness of European steelmakers. To solve this problem, the EU is going to introduce a сarbon border tax, a special tax on cheaper imports from countries with less stringent CO2 emission standards.