Dniprospetsstal

Dniprospetsstal is the largest producer of long stainless steel products in Ukraine. The company produces more than 800 grades of steel and alloys and more than 1,000 types of rolled products.

The main products of Dniprospetsstal are bars of stainless, tool, heat-resistant, high-speed and bearing steel, round bars 2–280 mm in diameter, including bars with special surface finish and of calibrated hexagonal cross section, as well as bulky forgings of round, square and rectangular cross section.

Production capacity

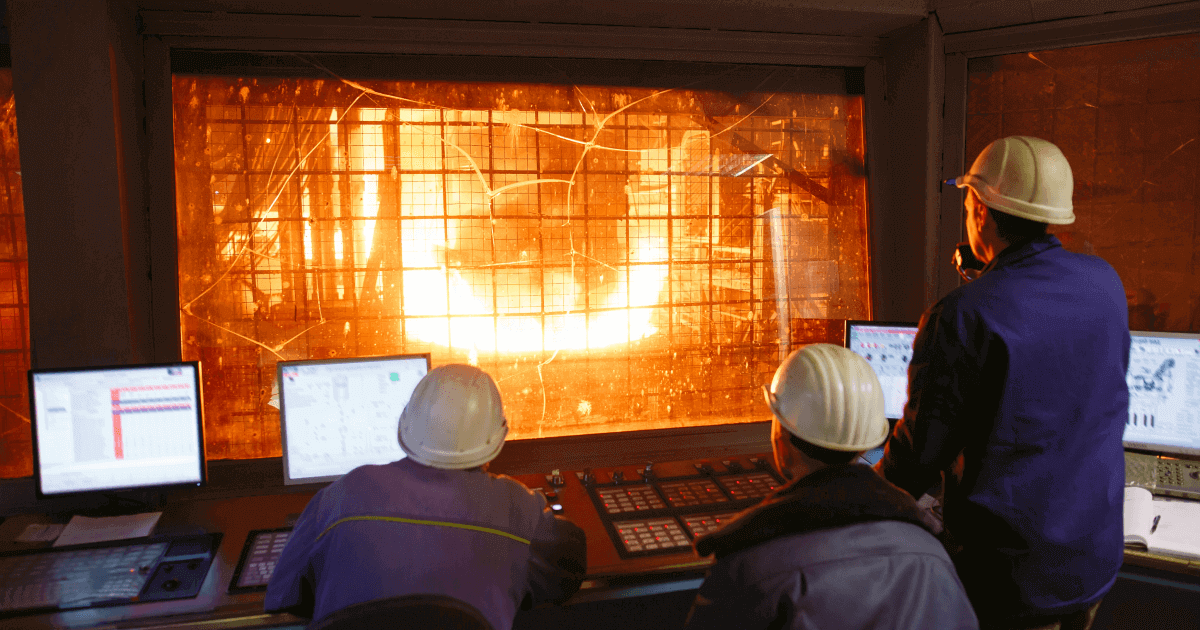

Steel melting shop 2: open electric arc furnace, argon-oxygen BOF, ladle furnace

Steel melting shop 3: ladle furnace, vacuum degasser

Steel melting shop 5: vacuum arc remelting furnace, electroslag remelting furnace

Sections mills 550, 325, 280

Calibration shop

Press forging shop: hydraulic presses of 60 MN and 32 MN

Forging shop: radial forging machines of 10 MN and 3.4 MN

Steel dressing and polishing shop: 2 turning and finishing lines

Staff and wages

* per worker before taxes

Charts and tables

Production results, thousand tons

Indicative sales structure by products in 2020*

Indicative sales structure by countries in 2020*

* structure of sales volumes, metric tons

Financial performance, $ million

| 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|---|---|---|

| Sales | 460.2 | 409.4 | 314.6 | 246.8 | 307.0 | 354 | 320 | 264 |

| EBITDA | 31.9 | 40.2 | 44.6 | 28.0 | 33.6 | 10 | 14 | -27 |

| EBITDA margin | 6.9% | 9.8% | 14.2% | 11.4% | 11.0% | 2.83% | 4.4% | -10.3% |

| Net income | 0.9 | -74.0 | -32.4 | -15.8 | 2.0 | -16 | 3 | -33 |

| Net income margin | 0.2% | -18.1% | -10.3% | -6.4% | 0.7% | -4.44% | 1.0% | -12.5% |

| CAPEX | 2.4 | 1.7 | 1.1 | 4.5 | 2.1 | 2 | 2 | 2 |

| Net debt | n/a | n/a | n/a | n/a | n/a | n/a | n/a | 130 |

Key facts

2021

Dniprospetsstal has modernized its steelmaking shop No. 2

2020

Dniprospetsstal announced its intention to participate in a project to localize production of electric locomotives for Ukrzaliznytsia (Ukrainian railway operator ).

2019

In 2019, the steel capacity utilization of Dniprospetsstal was 23.9%, while rolling capacity utilization amounted to 19.2%.

2018

Capacity utilization rate of Dniprospetsstal steel production units in 2018 was 26.9%, according to the 2018 Annual Report.

2018

According to the company’s management, after the imposition of import duties by the U.S. in 2018, Dniprospetsstal started to tap into the Canadian market. The Indian market was rated as promising as well.

In 2017

Dniprospetsstal began to work in China through local agents. Earlier, its products were supplied to the Chinese market under brands of other companies.

In 2017

Dniprospetsstal complied with the requirements of Ukraine’s national standards for technical parameters of rough axles for rolling stock locomotives and, thus, got the opportunity to manufacture new products for Ukrainian railways.

In 2015

The oxygen storage section was built, and equipped with facilities rented from Linde Gas Ukraine.

In 2012

Dniprospetsstal put into operation the ferromolybdenum production section in the steel melting shop 2.

Sources: websites of the companies, media outlets