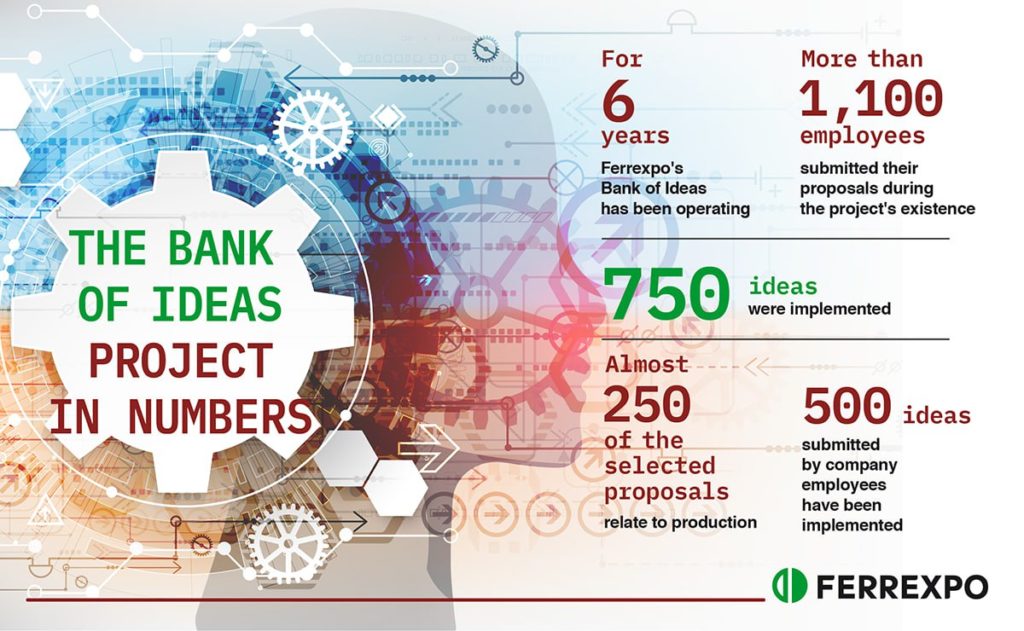

During the existence of the project, more than 1,100 employees submitted their proposals

Iron ore company Ferrexpo continues to review and implement proposals received through its own «The bank of ideas» – more than 1,100 employees submitted them during the project’s existence.

The way to improvement

The group is constantly working on modernization and improvement of production and business processes. The company’s continuous improvement system involves the implementation of initiatives aimed at achieving maximum efficiency in various areas of activity (operational, organizational, innovative, resource conservation). These measures are designed to increase profitability without attracting large investments. The Ferrexpo Project Office team is responsible for the systematic search for effective solutions.

In 2017, the company launched the «The bank of ideas» project, which encourages employees to find new ways for further improvement in various areas of Ferrexpo’s business, using their own experience. It is open to all employees of the group’s production enterprises. During the existence of the project, more than 700 ideas were taken for implementation, more than 500 of them were implemented. The largest number of selected proposals (246) related to production, 200 to repairs, and almost a hundred to improvement of working conditions.

Every year, the company holds contests in topical areas that require one or another solution, and the best ideas and authors are recognized with prizes.

The most active in submitting proposals, the company notes, are the employees of Poltava Mining. Representatives of production and repair departments constantly submit interesting initiatives to increase the efficiency of the work process or minor modernizations that can increase the service life of certain equipment. Many projects aimed at facilitating certain multi-stage production processes or improving the working conditions and operation of technical equipment are initiated by engineering and technical workers.

«Improving production processes is a topic that always worries caring employees, who are used to not just working a shift according to the job description, but live through all the processes that take place at the enterprise. Qualified employees who have a good understanding of the production process from the inside understand what changes are necessary to facilitate the work of colleagues, extend the maintenance period, and improve the efficiency of equipment. Such changes motivate others to join the process of continuous improvements for the benefit of the enterprise, in order to ultimately receive satisfaction and financial incentive from the successful implementation of their idea, as well as approval from management and colleagues,» noted Sergiy Byvalin, head of the investment and development service of Poltava Mining.

Offers are on time

In 2022, more than 100 ideas were submitted to «The bank of ideas», about 30 of them became projects of various levels. However, as the company notes, this is the lowest figure for the entire existence of the initiative, which was caused by the invasion of Russia and partial stops of the production process. For example, in 2021, «The bank of ideas» became a platform for more than 400 proposals. 2019 turned out to be a record year – almost 500 were submitted.

Employee initiatives are mostly about improvements that can be made with little or no investment, either by tweaking certain operational processes or by using previously used parts that are available in warehouses. Since the beginning of the full-scale invasion of Russia, the direction of the proposals has also changed somewhat. The company’s employees understand that with complicated logistics, ordering certain parts and spare parts abroad or in certain regions of Ukraine is not an easy task. So the ideas for now are focused on what is easier to implement in the current environment. Currently, Ferrexpo notes, there has been an increase in energy-saving initiatives, which are worth their weight in gold.

Open innovation

The company’s strategy also involves working with external ideas, as Ferrexpo has chosen the course of «open innovation», which is now used by thousands of business leaders around the world. This approach is aimed at studying trends not only in one’s own industry, but also in other sectors, interacting with universities and the scientific community to solve production problems. Priority directions for the group are scientific research and testing of the best available technologies for the development of an effective climate strategy, including testing of technologies of renewable energy sources. The company also annually finances research and development (R&D).

Despite the war, the group plans to launch the Ferrexpo | Innovation website – a «single window» of innovations that will be available to scientific, research and design organizations, etc. On this platform, you will be able to find relevant business problems, offer your projects or solutions that can help the company.

Ferrexpo is one of the largest investors in the Ukrainian economy with an average share of 2.5% in the total indicator of capital investment in industry. Since the initial placement of shares on the London Stock Exchange in 2007, the company has invested more than $3.3 billion in Ukrainian assets.

High investment activity has led to the fact that Ferrexpo’s assets are well invested. This makes it possible to invest more in development projects. The share of Ferrexpo’s investments in development projects is 63% on average, unlike other companies in the sector in Ukraine, which are forced to invest up to 70% in projects to support equipment in working condition. This potentially allows the company to grow at a faster pace and demonstrate greater efficiency.