Posts Industry Zaporizhstal 2627 09 January 2024

With an average load of 70% in 2023, the steel mill increased its steel production by 65%

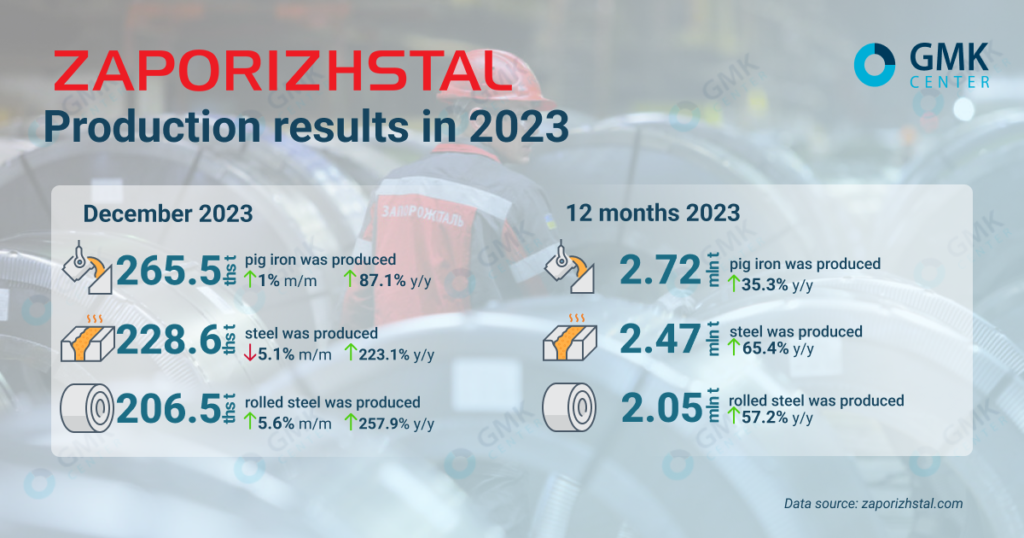

Unlike other steel enterprises, Zaporizhstal, a joint venture of Metinvest Group, in 2023 showed growth dynamics of production indicators many times better than the aggregate for the industry. At the end of last year, the growth rate of steel, pig iron and rolled products output at the plant was in the range of 35-65%, while the overall steel production in Ukraine at the end of the year showed a decline of 7-11%.

Industry example

The performance indicators of Zaporizhstal Iron and Steel Works are exemplary for the whole steel industry, as the enterprise’s workload in 2023 was the highest – on average it amounted to 70%.

In 2022, the steel mill showed such growth of production indicators:

- steel production – by 65.4% year-on-year, to 2.47 million tons;

- pig iron smelting – by 35.3% year-on-year, to 2.72 million tons;

- rolled steel output by 57.2% year-on-year, up to 2.55 million tons.

The significant increase in production was facilitated by the removal of blast furnace No. 2 from hot mothballing mode in March 2023 and the setting up of three blast furnaces. It should be reminded that after the beginning of the full-scale invasion of Ukraine by the Russian Federation, part of Zaporizhstal’s equipment was put into hot mothballing mode at the beginning of March 2022, but in April blast furnaces No. 3 and No. 4 were put back into operation. The company has a total of four blast furnaces with a combined capacity of 3.8 million tons.

“After we built cooperation with railroads and the Ministry of Infrastructure at the central level, and they started to give us corridors for the export of raw materials, we managed to launch «Zaporizhstal,” Olexander Mironenko, Chief Operating Officer of Metinvest, told previously.

The dynamics of production at the plant is completely different in a positive direction from the entire industry, which in January-November 2023 showed a decline of 7-11% in all key positions.

The improvement in production performance has also affected the financial results of the steel mill. In January-September 2023, Zaporizhstal reduced its loss by 92% y/y – to UAH 236.6 mln from UAH 2.9 bln. Over the same period, the company’s net income increased by 9.2% y/y – up to UAH 41.3 bln. In 2022, the steel mill had a loss of UAH 4.9 bln.

“The implemented anti-crisis solutions made it possible to stabilize the production process and reorient to more efficient work in the constantly changing wartime conditions, to keep production and retain the team,” Roman Slobodyanyuk, General Director of Zaporizhstal, notes.

New products

Last year, Zaporizhstal produced 14 new types of products (eight types in 2022).

- Semifinished products are slabs of different sizes made of S235, S275, S355 steel. They are delivered to Metinvest’s steel mills in Europe, where they are used to produce hot-rolled thick plate and coils. Production of slabs was planned to reach 60-80 thousand tons per month.

- Hot-rolled, cold-rolled and galvanized coils and sheets – various types of rolled products for construction and engineering according to EU, US and Ukrainian standards. In particular, Zaporizhstal started production of hot-rolled coils of S355J2 grade according to European standard EN 10025-2 and its Ukrainian analog DSTU EN 10025-2, which started to be supplied to Poland, Romania and others. The steel mill has also mastered the production of cold-rolled coil from structural steel grades S320GD and S350GD, intended for the production of galvanized coil used in the production of building steel structures at Unistil’s facilities. Previously, these products were produced at Ilyich Iron and Steel Works.

Technological innovations

Over the past year, the iron and steel plant has carried out many repairs, modernizations and implementations of technologies, among which the following can be noted:

- At the beginning of the year, Turkish compressors were installed at the enterprise, which should lead to savings of more than 700 thousand kW/h of electricity based on the results of last year.

- In June, the iron and steel plant completed the overhaul of blast furnace No. 3 (duration: 17 days), for which about UAH 200 million was allocated.

- In July, the first stage of overhaul of the hydrochloric acid regeneration unit in the cold rolling shop was completed to prevent discharges into the river. Dnieper. The cost of these works amounted to more than UAH 24 million. At the second stage, the main elements of the unit will be replaced.

- At the end of the year, the pulverized coal injection plant (PCI), which had previously been shut down due to unstable power supply and logistics constraints, was brought back into operation. The use of pulverized coal technology makes it possible to increase the productivity of blast furnaces by an average of 10-15%.

Prospects for the steel plant

Zaporizhstal is one of the key assets within the framework of Metinvest’s policy of «green transformation» of Ukrainian capacities. However, these plans had to be temporarily postponed amid the war.

“We considered the possibility of building electric melting furnaces at Zaporizhstal instead of an open hearth. We estimated the modernization of the steel mill at about $2 bln,” Yuri Ryzhenkov, General Director of Metinvest Group, noted.

This year, the steel plant sets itself a minimum goal of maintaining production at the 2023 level.

“In 2024, we plan to maintain production volumes, and with favorable conditions on foreign markets and demand for rolled steel in the domestic market, we plan to increase production capacity utilization,” emphasizes Roman Slobodyanyuk.

Before the war, Zaporizhstal worked with customers in almost 60 countries, now they are half as many. The war had an impact on the ability of the plant to fulfill orders for African and Middle Eastern countries. Increase in steel production and exports is possible with stable operation of the sea corridor, through which external supplies of steel products go.