News Companies Zaporizhstal 1089 19 June 2023

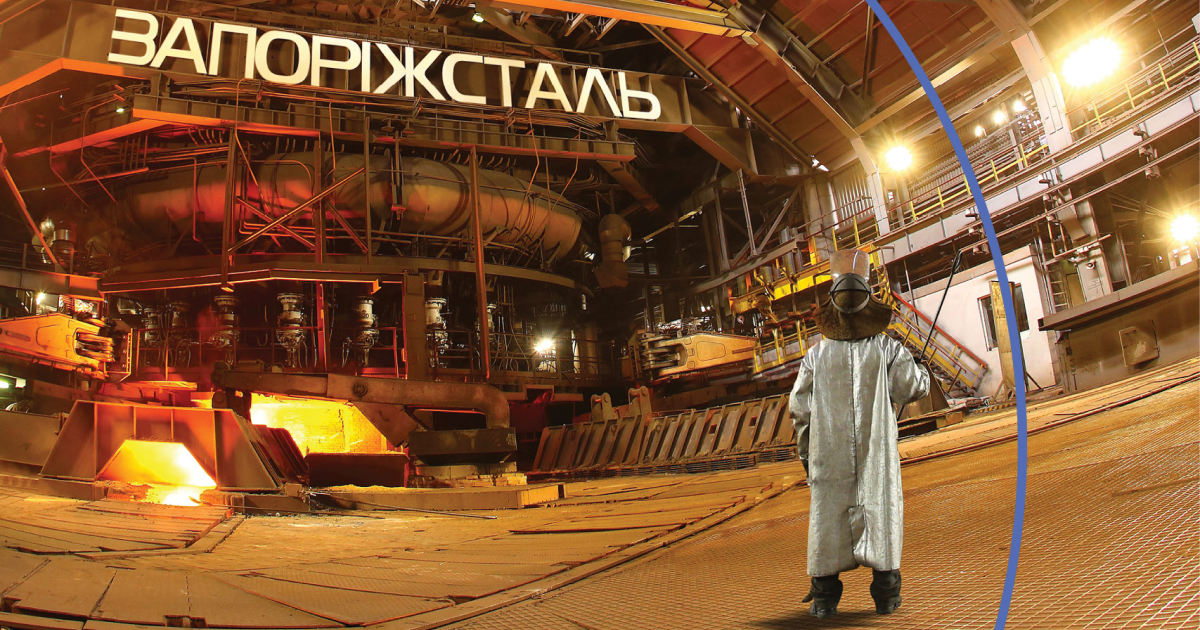

Specialists are currently blowing out the furnace. By the end of June, the unit will be at full capacity

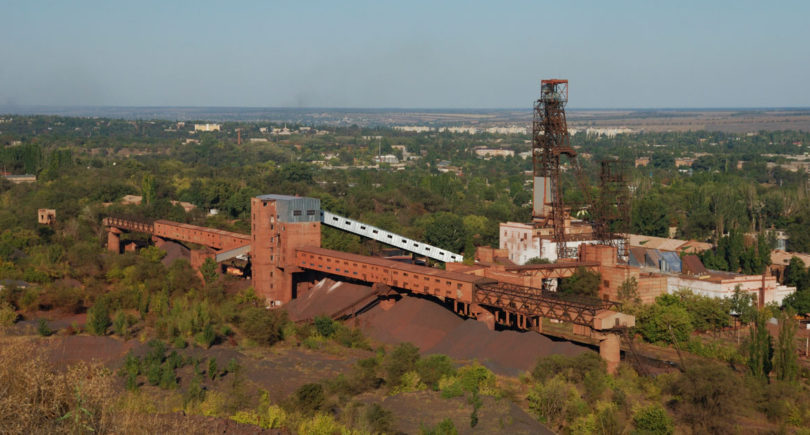

Zaporizhstal Iron and Steel Works has completed the major repair of blast furnace (BF) №3. This is stated in the press release on the company’s Facebook page.

For 17 days, almost 400 specialists of the plant performed important stages of repair, in particular, replacement of the blast furnace refrigerating plates and full shotcrete of the furnace. The refractory lining was also restored and all mechanisms were repaired. Furnace blowing is currently in progress.

«In order for the blast furnace to work not only efficiently, but also ecologically, we carried out full technical maintenance of the aspiration system and elements of modern gas treatment. Currently, an equally important stage is underway – blasting the blast furnace. So by the end of June, our blast furnace will be working at full capacity,» the report says.

BF №3 is equipped with modern control and measuring devices, which allow to automate its work as much as possible in accordance with the best global practices. The productivity of the blast furnace is almost 1 million tons of pig iron per year.

As GMK Center reported earlier, at the end of May 2023, Zaporizhstal reported about shutdown of blast furnace №3 for overhaul of the II category. Investments in the restoration of the unit were planned at the level of UAH 200 million.

In 2017, Zaporizhstal completely reconstructed BF №3 in a record time – 8 months instead of two years. At that time, more than 1.5 billion hryvnias were allocated to the implementation of a large-scale investment project.

In May 2023, Zaporizhstal increased rolled steel production by 45.9% compared to the same month of 2022 – up to 180.5 thousand tons. At the same time, compared to April, the indicator decreased by 12%, which is probably caused by the stoppage for the repair of BF №3