News Technologies Salzgitter 761 21 October 2022

Almost 100 tons of hydrogen gas have been used in annealing processes and galvanizing plants

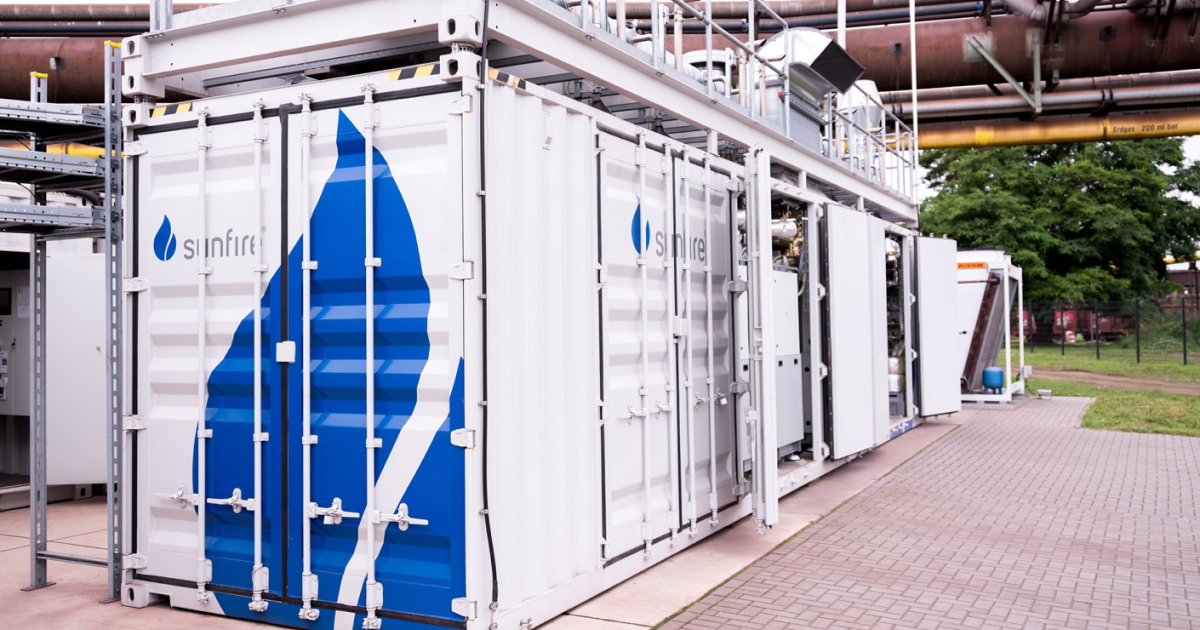

German steelmaker Salzgitter Group and electrolysis producer Sunfire have completed the EU-funded Green Industrial Hydrogen (GrlnHy2.0) project. Market Screener informs about it.

The project was completed with a record production of almost 100,000 tons of green hydrogen for the production of green steel.

According to Alexander Redenius from Salzgitter Mannesmann Forschung, GrInHy2.0 is an important part of the SALCOS project for CO2-reduced steel production, which requires green hydrogen. With the implementation of the project, the company received valuable information about the integration of electrolysis into production processes.

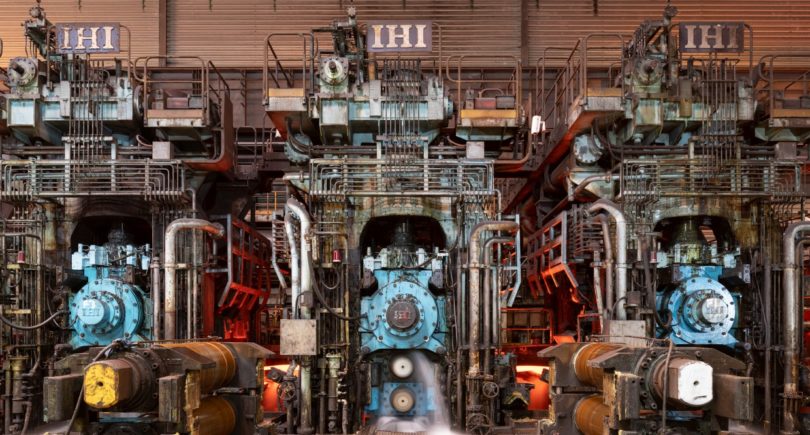

The produced green hydrogen is fed directly into the Salzgitter Flachstahl’s hydrogen network. So far, almost 100 tons of hydrogen gas have been used in annealing processes and galvanizing plants for steel finishing.

The world’s largest high-temperature electrolyzer Sunfire in Salzgitter is an important part of the Salzgitter Group’s sustainability plans. The project partners have been operating it since 2019 on the territory of the Salzgitter Flachstahl plant.

Alexander Redenius noted that high-temperature electrolysis is a very interesting technology in the steel industry, which will continue to be actively supported.

In addition to Salzgitter Flachstahl, Salzgitter Mannesmann Forschung and Sunfire, SMS Group Paul Wurth, Tenova and the French research institution CEA are also involved in the project.

As GMK Center reported earlier, Germany’s largest steelmaker ThyssenKrupp will allocate €2 billion for the construction of a plant for the production of green steel at one of its German plants. The project is planned to be implemented at the expense of state funding.