In particular, this includes wheeled rolling centers for locomotives and certain types of commuter electric trains

Ukrainian industrial company Interpipe has every opportunity to meet the needs of Ukrainian consumers with scarce railway products, in particular, wheel rolled centers for locomotives and certain types of suburban electric trains. Olexander Roslik, technical director of the company’s railroad division, said in an interview with CFTS.

“Previously, these scarce products were produced for many years by enterprises located in the eastern regions of our country, which now, given the current circumstances, are either not working or are directly in the war zone. Interpipe has every opportunity to meet Ukraine’s needs with wheel centers. Since the mid-2000s, the company has mastered the production and supply of wheel rolled centers with diameters from 905 to 1073 mm for different rolling stock of locomotives in such countries as India, Uzbekistan, the Baltic States and others,” he said.

Currently, the Ukrainian market needs wheel rolled centers for TE116 and ChME3 locomotives operated by the railroad, but Interpipe does not produce these products for Ukrainian consumers.

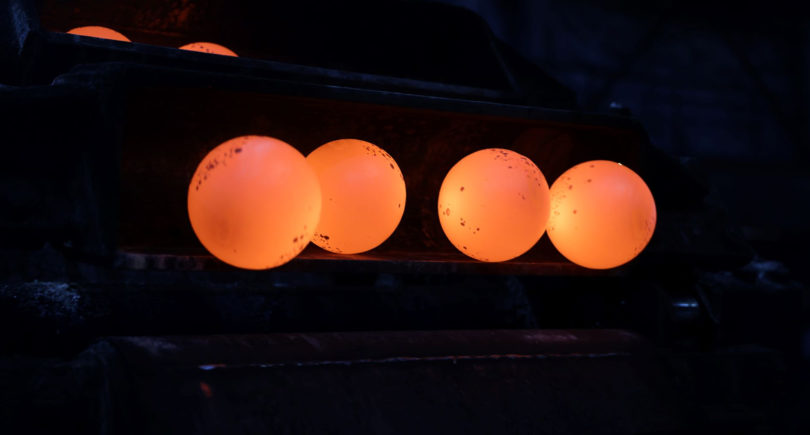

“The technology of manufacturing rolled wheel centers is based on the process of steel pressure treatment and is more modern than the technology of production of cast wheel centers. Using rolled technology improves the quality of products and their performance characteristics. It is established that the steel of rolled centers is much less contaminated with non-metallic inclusions in comparison with the steel of cast centers, microstructure of rolled centers is more homogeneous, mechanical characteristics of steel of rolled centers are higher in comparison with cast centers. Thus, the reliability and durability of wheel centers in operation depend on a set of properties and quality indicators, which are provided to them during the production process”, – stated Roslik.

As GMK Center reported earlier, Interpipe continues to invest in production to maintain competitiveness in international markets. In 2023, the company’s capex is estimated at $31 mln, which is 48% more than in the previous year. In addition, the company recently unveiled a major investment project totaling about $1 bln, involving the expansion of green steel production capacity.

In the first half of the year, the company increased production of railway products by 19.1% y/y – to 56,000 tons, in particular, railway wheels – 42,000 tons (+20% y/y). 9% y/y – up to 58 thousand tons. 40 thousand tons (+37.9% y/y) were sent to the European market, 9 thousand tons (-10% y/y) to the Ukrainian market.

Interpipe is an international vertically integrated pipe and wheel company, one of the top 10 seamless pipe producers in the world and one of the top 3 producers of solid-rolled railroad wheels.