The current workload of industry enterprises varies on average between 30-70%

After last year’s failure, the Ukrainian foundry industry has started to recover its production figures in 2023, but they are still far from double-digit levels. Despite the importance of the industry’s products for the Ukrainian defense industry, obtaining orders faces considerable bureaucracy. Dialogue with the state authorities – the main customer for defense products – is difficult, and even the change in the leadership of the Ministry of Strategprom in March 2023 did not significantly affect the situation.

Current situation

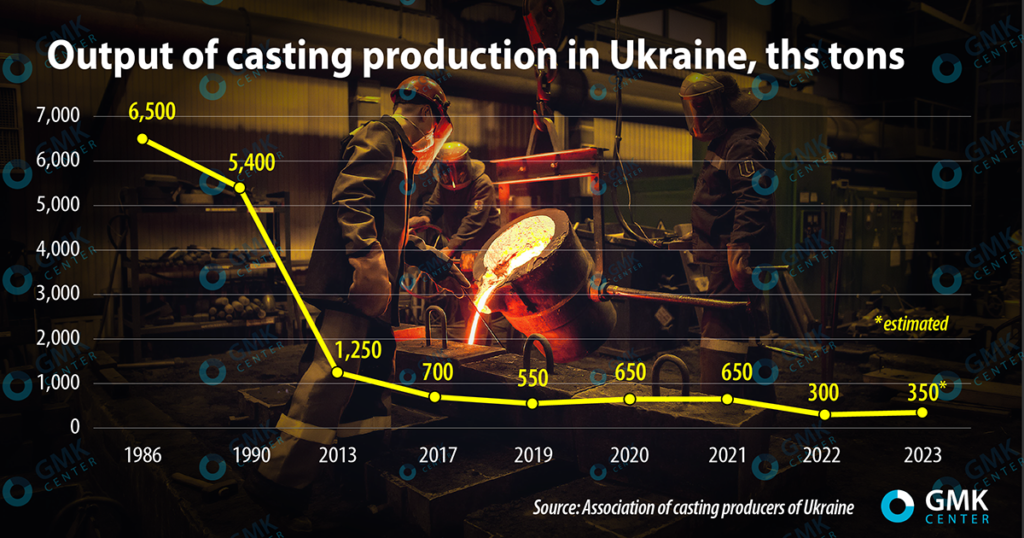

Now the foundry industry is experiencing production growth compared to the huge drop (on average by 50-70%) that we had in 2022. The foundry industry is expected to produce 350-400 thousand tons of products in 2023, but the exact figures will be known during the first quarter of 2024. In 2022, foundry output was approximately 300 thousand tons.

Foundry industry is more flexible than, for example, steel enterprises in terms of necessary infrastructure and equipment. Many foundries moved their facilities to safe areas as early as 2022 and restarted production relatively quickly. At the same time, they were forced to refocus on other products and other markets. They are also still far from reaching their full capacity. The current utilization of foundry enterprises varies, but on average it is in the range of 30-70%.

At the same time, a heavy blow to the industry was the cessation of work of many large enterprises located in frontline regions, which are physically impossible to move to other regions due to the large amount of large-size equipment.

The enterprises of the industry are trying to develop export of products, but many potential customers are scared away by the war in the country and its consequences – logistical difficulties, a lot of force majeure factors affecting production capabilities, etc.

At the same time, even in the current conditions, enterprises are introducing technological innovations, improving production processes, etc., which positively affects the quality of products.

Defense nuances

Under current conditions, defense orders are the salvation for the industry’s enterprises; the demand from the defense industry is high. It is now that the Ukrainian defense industry needs a wide range of foundry products – from components for weapons and equipment to protective structures. The potential of the industry is far from being fully utilized, so we are rather talking about opportunities than about the actual contribution of foundries to strengthening defense capabilities.

The factor that hinders the production of defense products is the presence of many intermediaries, which hinder the establishment of direct contacts between foundries and defense industry enterprises. Artificial problems are also created in passing design and technological documentation when promoting and mastering defense foundry products.

I would like to emphasize that at present the industry is developing only due to the initiative of foundry managers and professionalism of engineering and technical personnel who try to «break through» all bureaucratic walls and offer their products to the market. Many good initiatives and endeavors are ruined by bureaucracy and other obstacles in the environment of potential customers, including the defense industry.

Dialogue with authorities

Dialogue with the government is extremely important for foundries now, as it is the government that coordinates the work of defense industry enterprises, as well as the number and nature of defense orders. Today there is practically no dialog – everyone works on his own. Even the change in the leadership of the Ministry of Industry and Defense as the key government body responsible for the industry has not changed the situation significantly.

The executive power often generates some decisions that lead to nothing, as they are made in isolation and without taking into account the possibilities of the real sector of the economy. At the same time, the production is extremely necessary for the state to strengthen its defense capability and post-war restoration of infrastructure.

There is progress only at the level of local authorities and individual enterprises. The state has practically no strategic vision of the current and post-war development of industry.

Drivers of growth

In addition to the defense industry, the demand for foundry products can be driven by the construction industry, agro-industrial complex, railroads, power engineering and other industrial sectors, especially in the framework of reconstruction of destroyed infrastructure. For example, the construction of 1 km of road alone requires more than 500 tons of castings – rain drainage, manholes, etc.

Foundry workers can even partially replace metallurgists. At present metallurgical enterprises cannot provide all the products necessary for the country, so part of the issues of supplying the country with steel products at the initial stage of reconstruction of the destroyed infrastructure may fall on foundries. After a small technological re-equipment of production facilities, foundries can produce rebar, I-beams, channels, etc. in small volumes. This requires coordination with customers – government agencies and understanding of what products are needed to restore the infrastructure. Based on this, foundries can plan the work of their enterprises. At the same time, there is a quick return on investment in foundry production – the payback period is only 1.5-5 years.

The restoration of industry and infrastructure is necessary, first of all, for the financial and industrial self-sufficiency of the country, as we cannot constantly rely only on Western financial assistance.