News Global Market rolled steel production 3843 28 March 2024

The plant will produce flat products with low carbon emissions; the feasibility study was completed in March

Turkish investment company Ussuri Capital is planning to build a new low-carbon flat-rolled steel plant in Romania, S&P Global reports.

In March, the company completed a preliminary feasibility study and is currently conducting due diligence on land plots that could be used for the production facility.

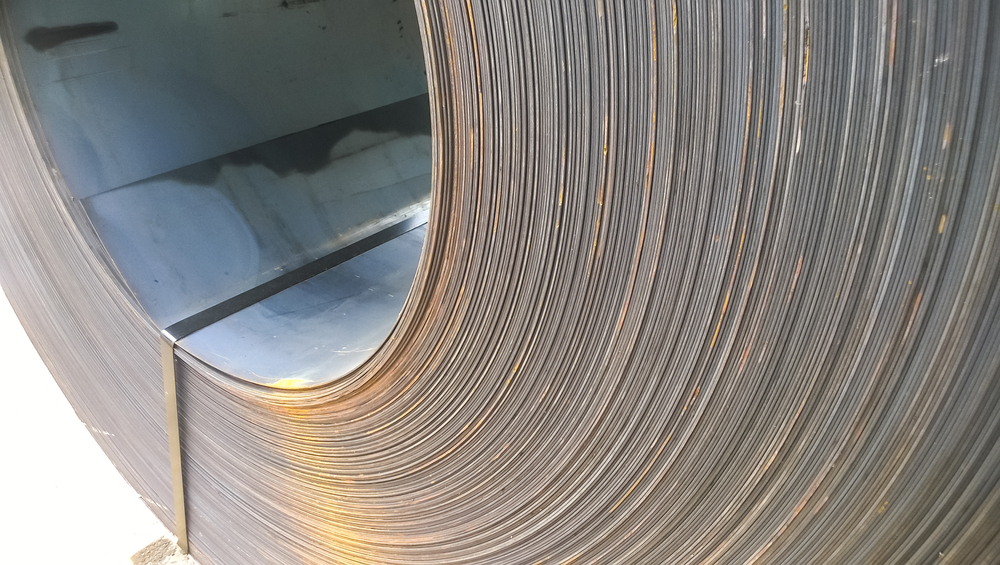

The project is being implemented from scratch and involves the installation of an electric arc furnace. The EAF will have a capacity of 1.2 million tons of steel per year and a continuous strip casting line with a capacity of 1.2 million tons of hot-rolled coils per year. Local scrap will be used in the production process. The plant is expected to be launched in 2027-2030.

Capital expenditures for the first stage (installation of pickling, hot-dip galvanizing and color coating lines and a cold rolling mill) are estimated at €160 million, and for the second stage (construction of an EAF and a continuous casting module) at €700-800 million.

The new plant in Romania is expected to produce 400,000 tpa of pickled coils, 250,000 tpa of cold-rolled coils and 250,000 tpa of hot-dip galvanized coils. While the electric arc furnace shop is ramping up, the plant will process hot-rolled coils imported from non-EU countries. Processing will start by 2027.

According to Ussuri Capital’s forecasts, in two years after the commissioning of Phase 1, the company’s revenue from downstream operations will reach €324 million.

As GMK Center reported earlier, steelmaker Industeel, a subsidiary of ArcelorMittal Downstream Solutions, has started construction of a vertical continuous casting machine (CCM) at its plant in Le Creusot, France. Investments in the project amount to €52 million. Once the unit is commissioned, the company will expand its product portfolio with lightweight slabs up to 35 cm thick.