News Companies investment 876 25 September 2024

The company estimates capital investments in the first stage of the project in Romania at €160 million

Turkish investment company Ussuri Capital announced, that officially entered the process of attracting investments in the amount of €60 million as equity capital to finance a new complex for the production of rolled steel in Romania. This is stated in the press release of the company.

Attracting financing is a strategic milestone in the development of the Ussuri Capital project. The funds will be used for the purchase of land, development of the project, purchase of basic equipment and construction of the main production complex.

As noted, the rest of the CAPEX will be financed through project financing.

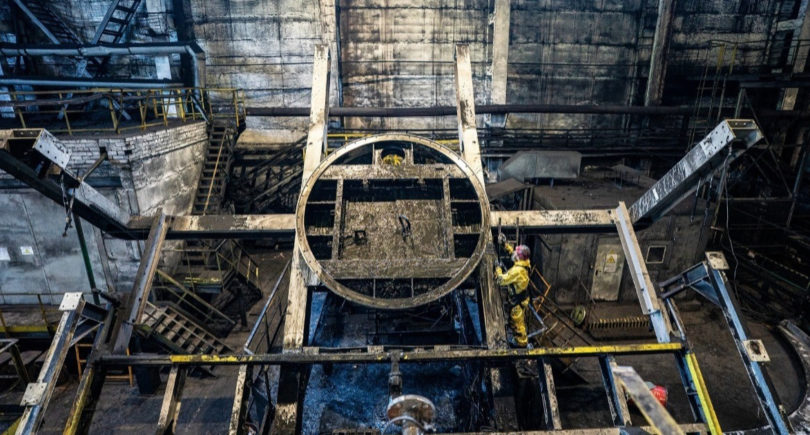

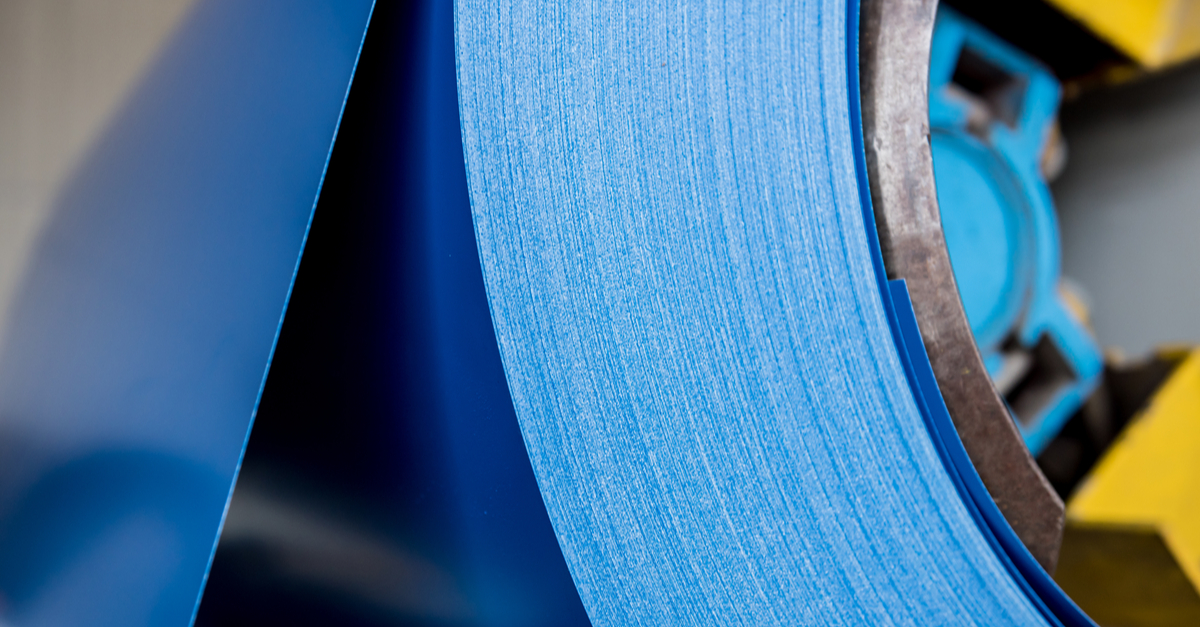

At the first stage, the company estimates capital investments at approximately €160 million – these are the funds needed to install a pickling line with a capacity of 400,000 t/year, a cold rolling mill with a capacity of 250,000 t/year, a hot-dip galvanizing line (250,000 t/year) and color coating lines (130,000 tons/year).

Ussuri Capital expects revenue of €324 million, EBITDA – of €38 million (EBITDA margin of approximately 12%), free cash flow – of €30 million two years after commissioning of the first stage equipment.

«Our company is at an exciting stage of development, and this round of equity capital is a key step on the way to the next stage of growth,» said Ussuri Capital Managing Director Roman Kurashev.

According to him, the company seeks to cooperate with investors who want to be part of the transformation of green steel industry in Europe. The CEO of Ussuri Capital is confident that the European steel market will become more protected from imports of flat products after the introduction of CBAM, and will allow value creation for market-oriented manufacturers.

As GMK Center reported earlier, Ussuri Capital plans to build in Romania, a new plant for the production of flat rolled products with a low level of carbon emissions. In March of this year, the company completed a preliminary feasibility study and carried out a comprehensive inspection of land plots on which production can be located. The project is being implemented from scratch, at the second stage it involves the construction of an electric arc furnace and a continuous casting module.