News Companies Central GOK 451 07 July 2023

Equipment repair work was carried out to ensure uninterrupted production of high-quality pellets

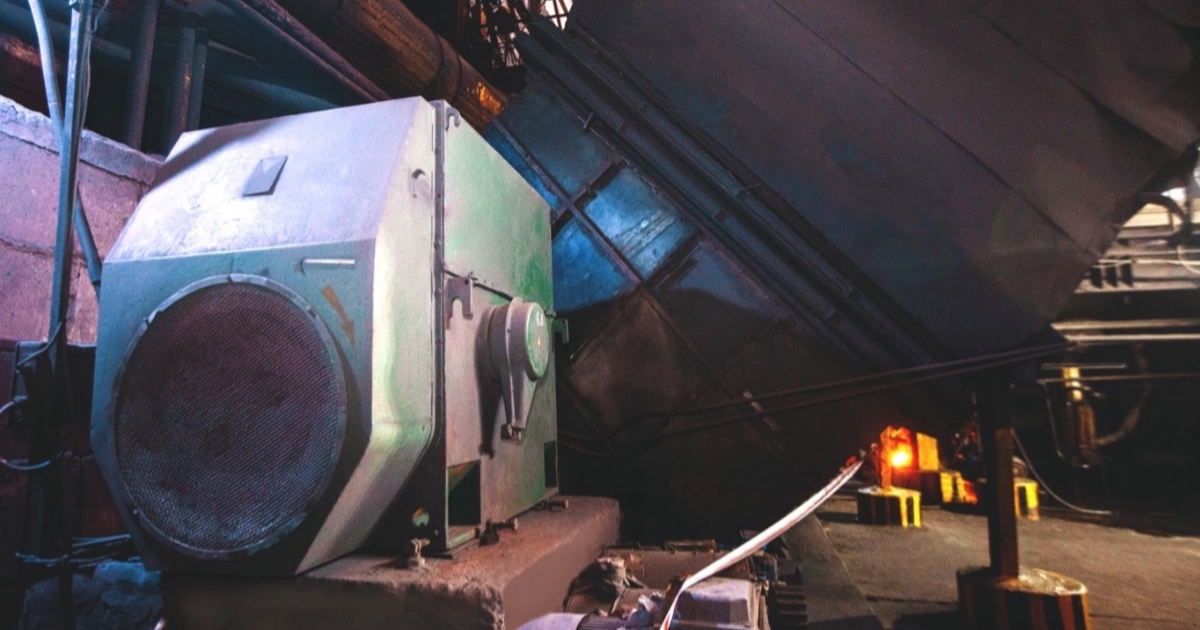

The Central Mining and Processing Plant (Central GOK) of the Metinvest Group completed the overhaul of the OK-324 roasting machine at the clod factory. This is stated in the press release by Metinvest.Media.

During the repair, specialists updated the machine horn and replaced the refractory lining. To do this, the pre-chambers were covered with fire-resistant bricks of the Slovak firm REFRAKO and Zaporizhvognetryv. The total amount of material for these works is estimated at 100 tons.

To reduce the environmental burden and increase energy efficiency, the gas ducts of the D-5 smoke extractor were repaired with the replacement of pockets. Also, the D-2 smoke extractor pipe was replaced and the D-2 droplet catchers were repaired. This will contribute to the improvement of the fume hood and effective cleaning of the gas stream from dust.

A new rotor was installed on the D-1 smoke extractor, which is an important part of the OK-324 roasting machine. This device takes the heated gases from the cooling zone and supplies them to the drying zone, which contributes to the efficient drying process of the pellets before the thermosetting process.

In addition, four conveyor belts on conveyors OB 6-7, KP 2-7, OB 7, OB 4-7 were replaced as part of the overhaul.

«For uninterrupted production of high-quality products, we replaced and repaired components and mechanisms that cannot be carried out during factory operation. In two weeks, the experts carried out work to diagnose the serviceability of all systems and units, of which there are more than 200 at the factory. Thanks to effective measures, the entire complex of factory equipment is ready to work with high reliability and productivity until the next scheduled overhaul,» said the head of the Central GOK coagulation factory Andriy Zhilkinskyi.

As GMK Center reported earlier, the Central GOK installed modernized a bowl flocculator in a flocculation plant to ensure a stable pellet production process.