News Companies Northern GOK 395 12 January 2024

The enterprise replaced the vacuum pump in the dewatering section of iron ore processing factory No. 2

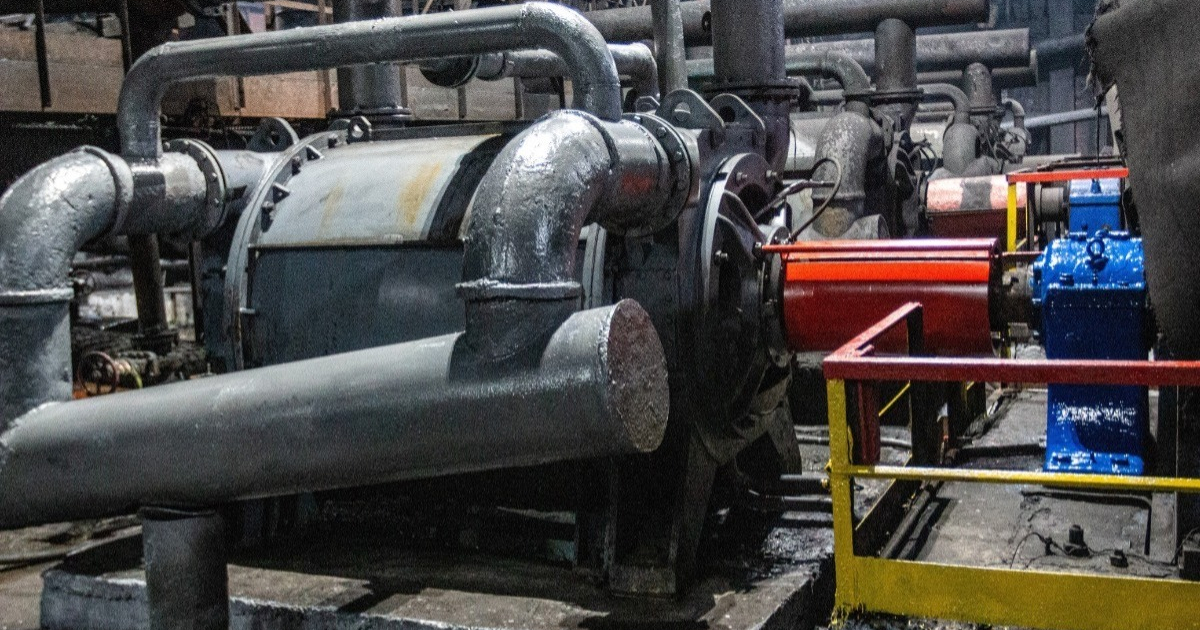

Northern Mining, part of Metinvest Group, has allocated UAH 3.2 million to improve the quality of iron ore concentrate. The company replaced a vacuum pump at the dewatering section of the ore dressing plant No. 2. This is reported by Metinvest.Media.

In the process of concentrate production at the ore dressing plant No. 2 (OPF-2), VNN2-300 vacuum pumps are used. They are used to create a vacuum in the overall system during concentrate dewatering. In total, the plant has 18 units of such equipment, of which 17 are constantly involved in the technological process and one is a backup.

«Due to the wear and tear of one of the vacuum pumps at the factory, it was dismantled and new similar equipment was installed,» the report says.

In 2024, two more units of pumping equipment are planned to be replaced with new ones at ore beneficiation plant No. 2 of Northern Mining.

“The vacuum pump that we replaced had effectively served its useful life, even with a surplus. It was replaced by a new one of the same modification. With it, we will ensure the rated performance and the required vacuum level in the system, which will allow us to reduce the total number of vacuum pumps in operation in the process and bring a reduction in energy consumption,» the head of the OPF-2 Andriyan Myshko said.

As GMK Center reported earlier, the Northern Mining set up production hof omogeneous pellets with an iron content of more than 65%. The company’s technologists applied operational improvements in the technological chain of concentrate and pellet production, so that iron ore met the requirements of European steelmakers.