More than 1,700 repairs of the main production equipment were carried out

Metinvest Promservice’s (MPS) specialists performed more than 5,500 repairs at the Zaporizhstal Iron and Steel Works during the year. It is stated in the message on the company’s Facebook page.

In this period, 1,776 repairs of main production equipment and 3,748 repairs of auxiliary equipment were carried out. Teams of four divisions of the Metinvest Promservice repair and service department participated in the works: the rolling equipment repair shop, steel equipment repair shops № 1 and № 2, and the electrical equipment repair shop for steel shops.

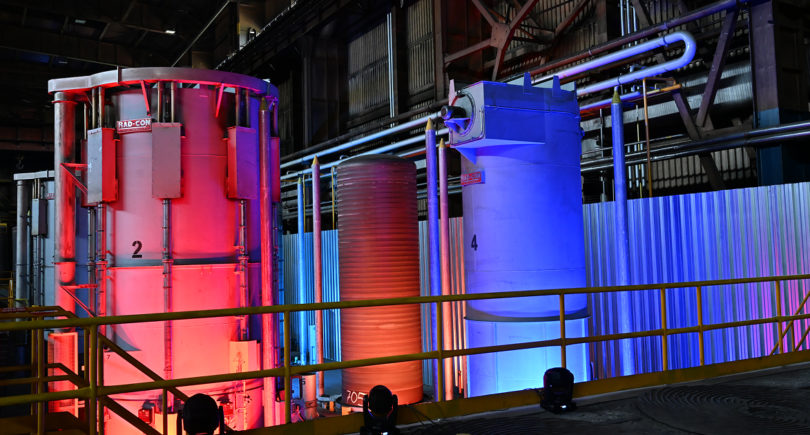

The most active repair and restoration activities with the participation of Metinvest Promservice’s specialists took place in the agglomeration, blast furnace and hot rolling shops. In addition, the MPS team for the first time carried out overhaul of large-diameter pipelines in the water supply shop at Zaporizhstal, as well as repairs of the power equipment of the thermal power plant and the oxygen converter shop.

The largest projects were carried out in the Marteniv and blast furnace shops of the steel plant. In the Marteniv shop, an umbrella cover was made for the barrel of mixer № 1, in the second case, the DANCU reducer of the backfilling apparatus of the blast furnace was repaired.

As GMK Center reported earlier, Zaporizhstal and Kametstal despite the war are expanding product line. For example, Zaporizhstal’s specialists started the production of cold-rolled double-mass roll without a weld, intended mainly for the construction industry.

Also, Zaporizhia Foundry and Mechanical Plant (ZLMZ) set up the production of lances for the steelmaking production of the Zaporizhstal Iorn and Steel Works.