News Companies environment 1789 25 June 2021

The Group is considering Mariupol and Zaporizhia as potential construction sites for a new EAF steelmaking plant

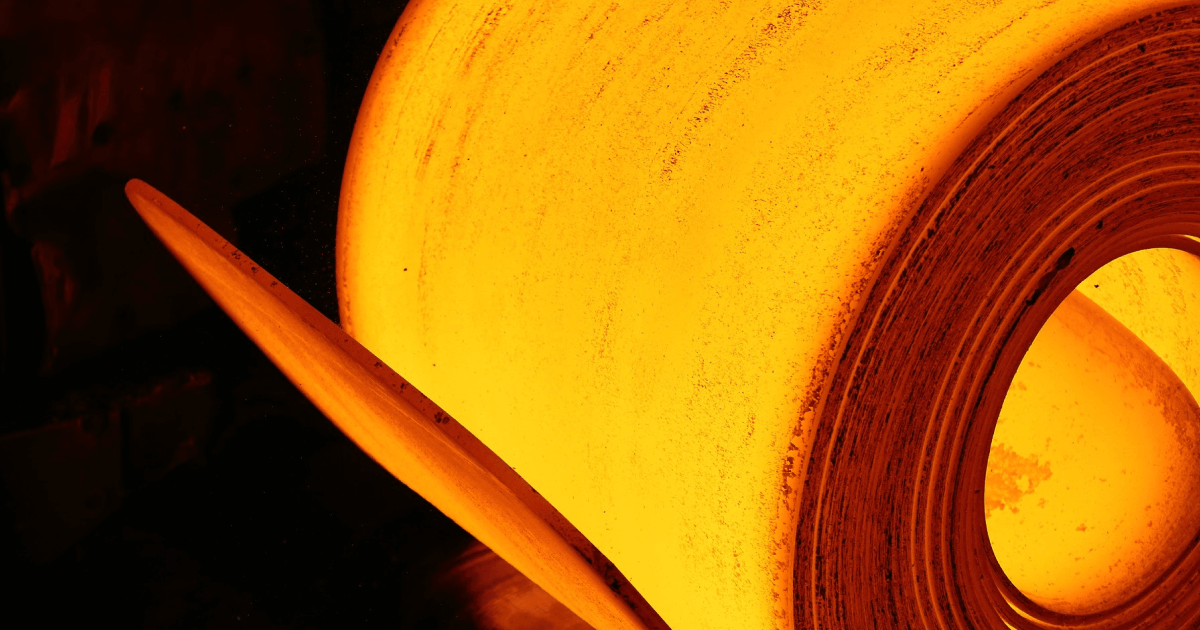

The Metinvest Group is exploring a possibility of building an integrated EAF steelmaking plant. The investment in construction of the new asset is estimated at $3.5–4 billion.

Metinvest CEO, Yuriy Ryzhenkov, shared this insight at a press conference dedicated to Metinvest’s 15th anniversary.

A new EAF steelmaking plant will comprise two DRI modules, two electric-arc furnaces and two continuous casting machines.

“With the transition to EAF steelmaking, traditional facilities will have to shut down, and that’s normal. We are changing the technology, which means we are taking it to the next level. With the budget available today, the plant we are having in mind could include two modules for direct reduction of iron, two electric-arc furnaces and two continuous casting machines. According to our rough estimates, the cost of construction will be around $3.5–4 billion,” says Mr Ryzhenkov.

According to him, two sites are presently being considered for the construction of a new EAF asset — Mariupol and Zaporizhia.

The CEO says that new technologies will help reduce the impact of industrial production on the environment. The Group believes the technologies of the future are EAF and hydrogen-based steelmaking. That is why Metinvest is considering the idea of creating a brand new steelmaking plant at one of the production sites. That is a target for the next 10 years.

Mr Ryzhenkov adds that Metinvest already produces the necessary raw materials, DRI pellets, at the Central GOK. The Northern GOK will also produce raw materials, after the completion of a flotation facility for enrichment of iron ore concentrate and a new roasting machine.

Natural gas-based DRI technology is used to produce EAF steel. Gas can be replaced with hydrogen, which can help reduce greenhouse gas emissions to zero.

“At the first stage, we might combine BF, DRI and EAF routes. That would be even more efficient,” underlines Mr Ryzhenkov.

The Metinvest CEO points out that the transition to EAF steelmaking will significantly reduce the need in coke. Because there will be no longer need for it in steelmaking, some coke plants may have to be shut down, he added.

Mr Ryzhenkov particularly emphasizes that Zaporizhstal Integrated Iron & Steel Works will have to either remain a pig iron plant in its final days, or to switch to EAF steelmaking. Ilyich Iron and Steel Works of Mariupol will retain its classic production route for the foreseeable future.

Mr Ryzhenkov says that Metinvest is now doing its best to reduce the company’s debt burden. It will make it possible for the Group to raise project financing, for this new construction project among other things.

As reported earlier, at the end of 2020, the Metinvest Group reported investments in environmental projects in the amount of $200 million. Last year, the company completed reconstruction of a sinter plant at Ilyich Iron and Steel Works.

Metinvest Holding LLC is the managing company of the Metinvest Group. The major shareholders of Metinvest are its co-managing companies SKM Group (71.24%) and Smart Holding (23.76%).

In 2020, the company declared an ₴8 billion investment in protecting the environment in Kryvyi Rih. The Group previously reported that its investments in environmental projects in Mariupol amounted to ₴15.3 billion over the period of 9 years.