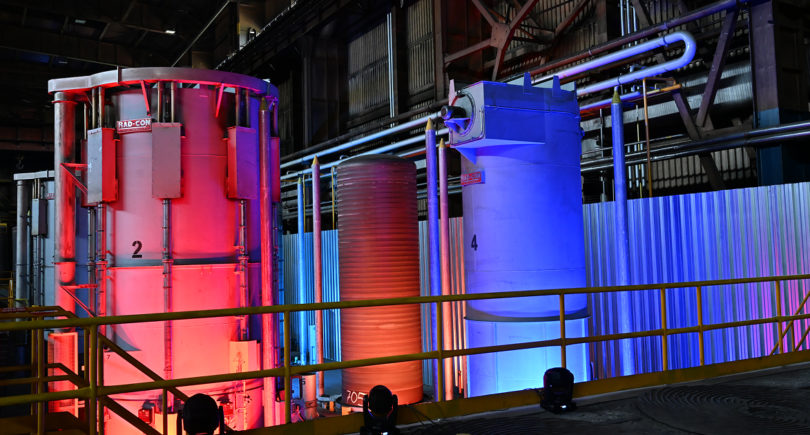

The unit is used in the heat treatment section of the steel casting workshop

Metinvest Kryvyi Rih Machining and Repair Plant (KMRP) carried out major repairs of a 20-ton electric bridge crane at the heat treatment section of the steel casting workshop. Metinvest Kryvyi Rih reports about it on its Facebook page.

Specialists updated the crane control system and replaced cable materials. A comfortable chair was installed in the cabin, a heating and air conditioning system was also installed, and a loudspeaker was installed for convenient communication with colleagues.

“Thanks to modern technology, the driver has everything to perform work tasks productively and comfortably,” the company notes.

Previously, an electric overhead crane with a load capacity of 16 tons was installed in the mechanical assembly shop of KMRP after major repairs.

As GMK Center reported earlier, in August Metinvest-KMRP launched the MA4134A pneumatic hammer in the steel construction shop, the operation of which was suspended 10 years ago. Thanks to the restoration of the hammer, Metinvest-KMRP will be able to expand the range and quantity of manufactured products.

Earlier, KMRP produced wooden models for casting unloading and loading trunnions. Casting of parts will be done by Kametstal specialists, and after casting, the parts will be handed over to the enrichment factories of Ingulets Mining.

KMRP produces and repairs equipment for mining and metals enterprises of the Metinvest group. The enterprise has a metallurgical complex with a closed cycle. The plant produces parts from more than 40 grades of steel and alloys, assembles and welds products from steel sheet metal and long products.