The third stage of air heater No. 6 at Blast Furnace No. 9 is currently undergoing overhaul

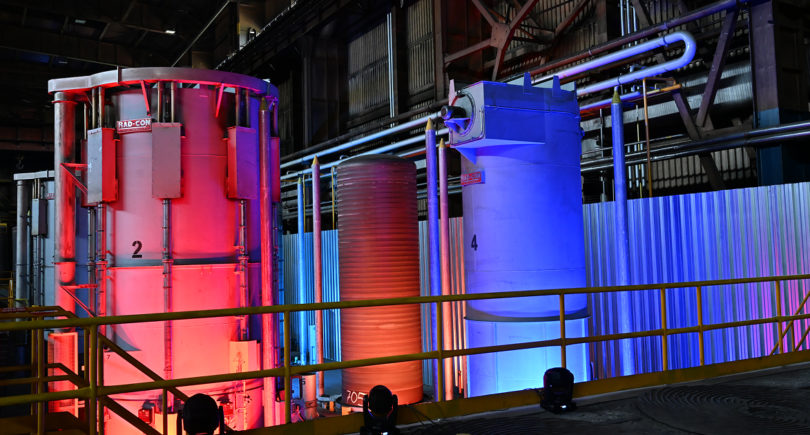

Kametstal has launched the first stage of this year’s overhaul of air heaters in its blast furnace shop. This is stated in the company’s message on its Facebook page.

The third overhaul of the third category of air heater No. 6 (AH-6) at blast furnace No. 9 is currently underway. During the work, Metinvest-Promservice specialists are primarily performing partial repairs of the refractory lining of the combustion chamber, hot and cold blowing and gas burner fittings, smoke valve fittings, upper rows and corners of the nozzle chamber, dome, and cleaning the nozzle openings of the unit. In total, 300 tons of lining worn out during operation need to be replaced.

The overhaul plan also includes a partial upgrade of cabling and wiring products and command and control equipment, replacement of control panels and lighting network, gas throttle and repair of the gas burner fan.

According to Yevgen Podgorny, Deputy Head of Blast Furnace Shop for Engineering, stable operation of air heaters plays an important role in fuel saving and increasing the productivity of blast furnaces, and thus is very important for the efficient operation of the shop.

«Last year, three air heaters were overhauled. The overhaul of BF-6 at Blast Furnace No. 9 is the next step in the implementation of the capital repair program, which will allow us to improve the technical and economic performance of the main equipment,» he said.

The air heater is one of the key communication units designed to heat the blast entering blast furnaces during pig iron production.

As GMK Center reported earlier, Kametstal has completed the repair of Blast Furnace No. 9 of the third category ahead of schedule. The contractor for the work in the blast furnace shop was Zaporizhvognetryv and Metinvest Promservice.