News Companies ArcelorMittal Kryvyi Rih 789 03 December 2024

The laboratory has been restored after being damaged by a rocket attack in 2022 and is equipped with modern equipment

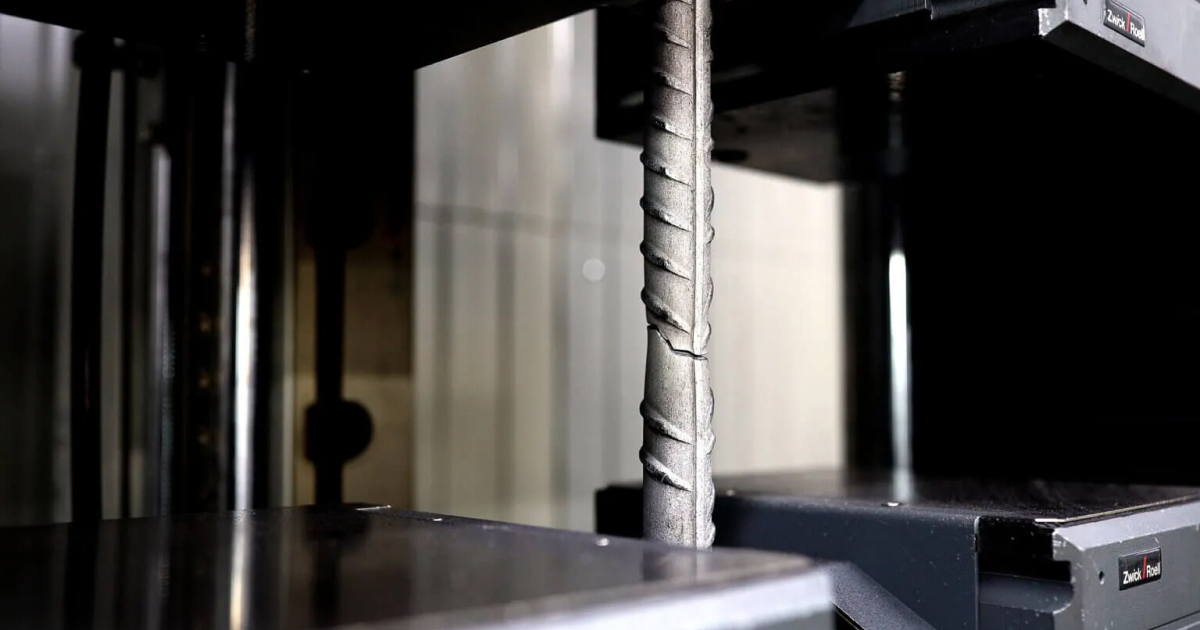

PJSC ArcelorMittal Kryvyi Rih has launched a new laboratory for physical, mechanical and metallographic testing at its rolling department, replacing the one destroyed during a rocket attack at the end of 2022. This is stated in a press release of Metallurg newspaper.

“In fact, we have put into operation a new laboratory for physical, mechanical and metallographic tests using the staff of the rolling department, the quality department and the central maintenance and repair department. We used the premises that used to be a small smithy as a basis,” comments Sergey Andrusenko, Head of the Quality Department’s Test Center.

The laboratory was equipped with new German testing machines that ensure accuracy and safety. In particular, they are equipped with multi-level emergency protection systems to avoid risks to personnel. These machines are capable of withstanding heavy loads, for example, testing the strength of rebar under a pressure equivalent to 160 tons.

The laboratory significantly speeds up the process of setting up rolling mills. According to Sergey Andrusenko, rolled steel samples are now tested on site and the results are available in 5-10 minutes, which allows for prompt adjustments to production processes.

Employees note the improvement in working conditions. Laboratory technician Anna Vedmedenko emphasized that the new equipment is safer and more convenient, and the working environment is more comfortable. The upgrade includes air conditioning, electric heating and optimal workspace organization.

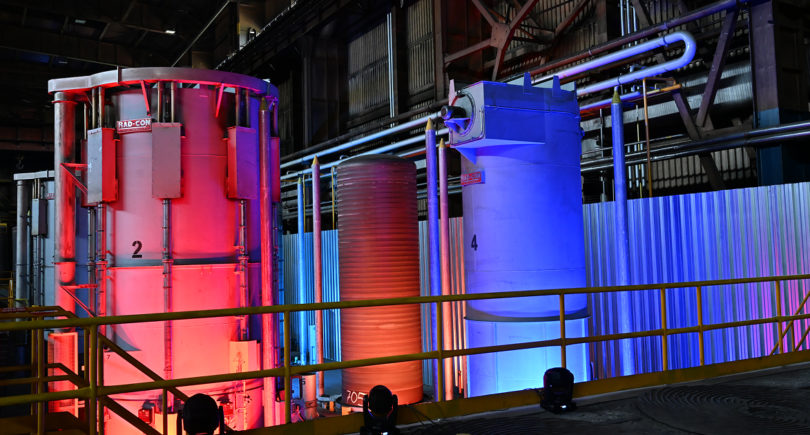

Earlier this year, ArcelorMittal Kryvyi Rih set a record by producing 60 heats in one batch at continuous casting machine (CCM) No. 2. The achievement demonstrates not only the high level of professionalism of the employees, but also has important economic implications, as it reduces production costs and billet costs.