News Companies ArcelorMittal Kryvyi Rih 880 27 October 2022

The unit allows the plant to expand the range of orders for its own and external orders

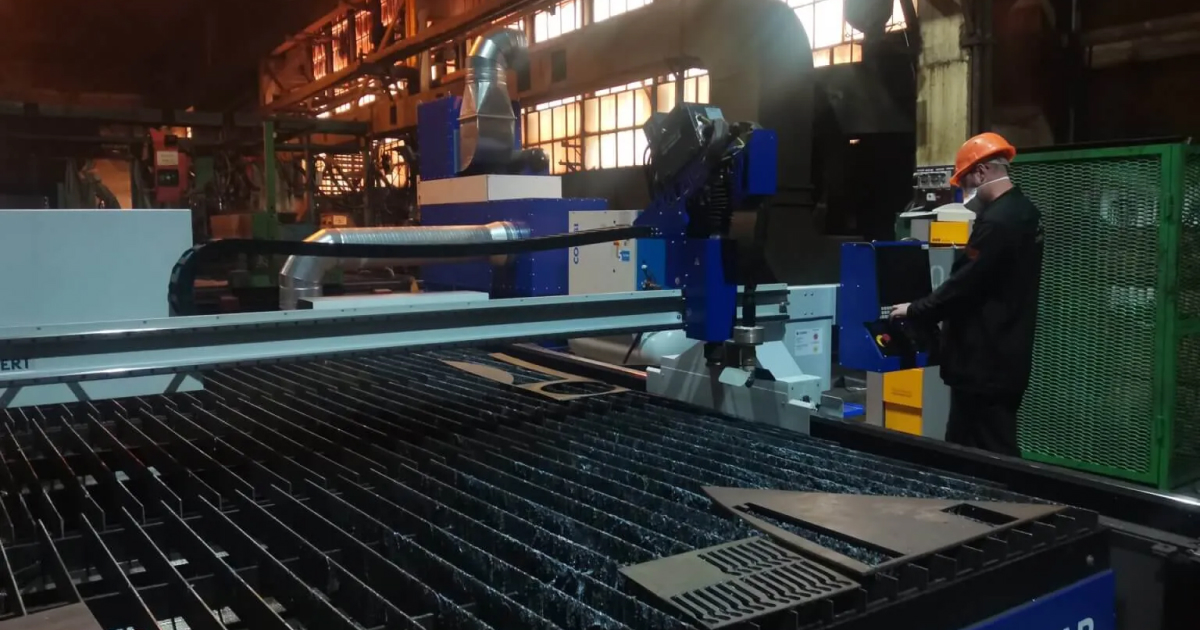

ArcelorMittal Kryvyi Rih installed a new plasma cutting machine ECKERT Jantar in the steel structure shop of the Foundry and Mechanical Plant. This is stated in newspaper “Metallurg’s” press release.

The unit can cut out any part of the most complex shape from carbon and stainless steels. If necessary, the functionality of the machine can be increased by installing additional optional equipment.

With the help of the machine, the specialists of the plant have already made starting tips for continuous casting machines, flanges for connecting pipes, slotted screens for blast furnaces and mining and processing plants.

“There are only five such machines in Ukraine, and we have one of them. The presence of a plasma cutting machine allows us to expand the range of orders, quickly and efficiently fulfill them not only for the workshops of our enterprise, but also for external customers. Now the part is cut faster without loss in quality. And the machine helps to save energy, because it consumes less electricity. Now it is very important!” said Sergiy Antoshkin, Deputy Head of the Central Metallurgical Plant for ArcelorMittal technology.

As GMK Center reported earlier, ArcelorMittal Kryvyi Rih put into operation a new welding robot-manipulator in the steel construction shop of the Foundry and Mechanical Plant. Now the robot performs welding in hard-to-reach places.

Also, ArcelorMittal Kryvyi Rih carried out scheduled repairs of the 140-ton excavator №55 in quarry №3 of the mining department. In total, 11 excavators of various models with bucket volumes from 5.5 to 12.5 cubic meters are operated in quarry №3.