News Companies rolled steel production 761 17 January 2025

New technologies were introduced in the hot rolling shop, processes were optimized and resource consumption was reduced

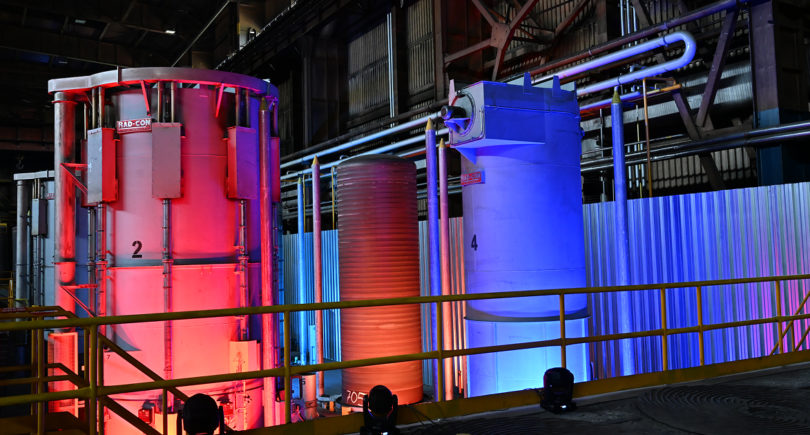

Zaporizhstal’s hot rolling shop has demonstrated high efficiency, generating a total economic effect of $618 thousand in 2024. Thanks to a professional approach and rational use of resources, the rollers not only achieved significant savings but also improved production processes, the company said in a statement.

One of the key achievements was an increase in the stability of horizontal rolls at the Slabbing 1150 mill. This made it possible to roll 20 thousand tons more metal per cladding, which brought an economic effect of $18 thousand per year.

The specialists also implemented a combined technology for processing slabs. This helped to significantly reduce rejects, which resulted in additional savings of $125 thousand.

Another important achievement was the reduction in metal consumption. Thanks to a set of measures, the amount of scrap was reduced by 2.2 kg per ton of rolled products. This optimization brought a record result of $475 thousand in savings over the year.

“The Hot Strip Mill Shop is a true professional. The team performs its work with excellence and systematically implements effective measures to improve production and reduce costs,” the company said.

As GMK Center reported earlier, in 2024, Zaporizhstal increased its production of commercial rolled steel by 18.3% year-on-year to 2.43 million tons. The company produced 3.11 million tons of pig iron in the year, up 14.3% y/y, and 2.89 million tons of steel (+17.2% y/y). Despite the proximity to the frontline, security risks, a significant shortage of staff, energy supply constraints and stagnant global steel market, the company continues to operate and increase production.