This will contribute to a significant increase in the production of high-quality steel, in particular for the automotive industry

Swedish steelmaker SSAB has signed an agreement with Germany’s SMS Group to supply equipment and process automation for a new cold-rolled steel production facility in Luleå. The project is part of the construction of a modern mini-mill, which the company decided on in April 2024 as part of its transformation to carbon-free steel production, according to a press release.

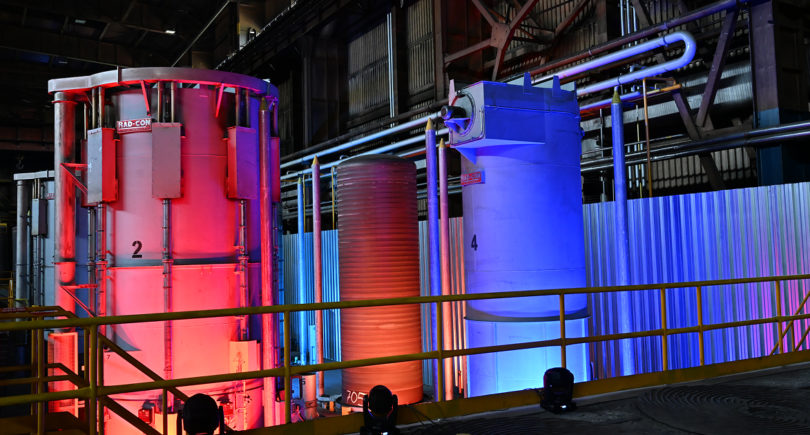

The new cold rolling complex will allow SSAB Europe to significantly increase its production of high-quality steel, in particular for the automotive industry. The equipment to be supplied by SMS Group will include a pickling line with a multi-roll mill, continuous annealing and galvanizing lines, and automated inspection systems.

All furnaces in the complex will be electric, which will ensure a minimal carbon footprint. Innovative technologies, including full digitalization and the use of robotic systems, will guarantee high efficiency and production stability.

The new Luleå plant is expected to reduce CO2 emissions by 2.8 million tons annually, and SSAB’s transformation will reduce greenhouse gas emissions in Sweden by 10% overall. This will be a significant step towards a sustainable future for the entire European steel industry.

As GMK Center reported earlier, in early December 2024, SSAB announced that it had raised SEK 1.45 billion (€126 million) in financing under the Just Transition Fund, established by the European Union to support the environmental transformation of industry. The purpose of the financing is to accelerate the transition to zero-carbon steel production, including the modernization of the company’s production facilities in Luleå.