Thanks to coordinated work, enterprises achieved an economic effect of $1.4 million in October

In late fall, Metinvest Group’s mining and processing plants (Minings) are stepping up their operations by introducing innovative approaches to improve production efficiency, Metinvest Kryvyi Rih said in a statement.

In October, the ore dressing and pelletizing departments of the Minings, as a result of the implementation of energy efficiency measures, provided a total economic effect of $1.4 million.

The ore dressing plants, in particular, the concentrator-1 at Northern Mining, achieved savings of $1.1 million. One of the key measures was to reduce the consumption of process water by stabilizing the pressure in water pipes. This approach not only reduces costs but also has a positive impact on environmental performance.

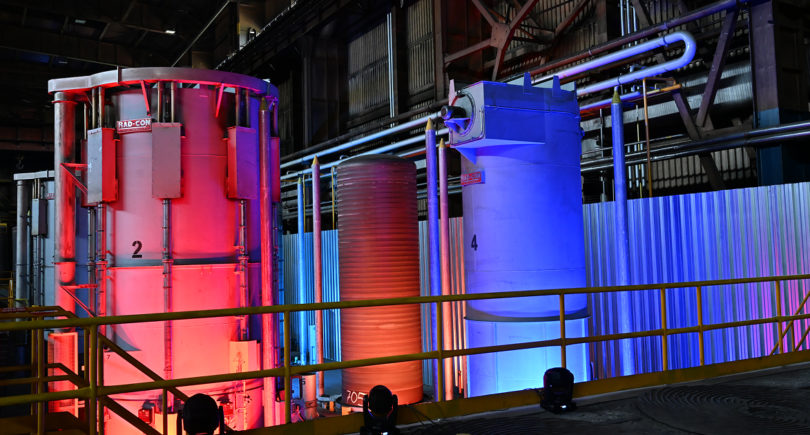

The pelletizing plants of Central and Northern Minings added another $0.3 million to the team result. A significant contribution was made by the supply of biofuel to burners No. 13-14 at Central Mining, which reduced the use of natural gas. In addition, Northern Mining installed a roller screen at CPO-2, which helped improve product quality and reduce bentonite consumption.

As GMK Center reported earlier, in the third quarter of 2024, the company reduced the production of iron ore concentrate (total) by 17% compared to the previous quarter to 3.35 million tons. Production of commercial iron ore products in the period amounted to 3.23 million tonnes (-15% q/q), including 1.85 million tonnes of concentrate (-16% q/q) and 1.38 million tonnes of pellets (-14% q/q).