The unit is designed to generate saturated steam for the production of its own electricity on counterpressure generator №7

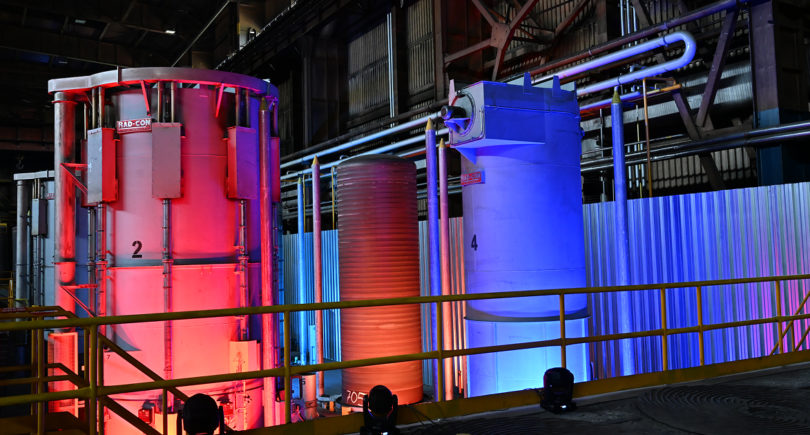

Kametstal Iron and Steel Works has started long-term overhaul of boiler unit №11 in the thermal power plant. This is stated in the press release on the company’s Facebook page.

The unit is designed to generate saturated steam for the production of its own electricity on counterpressure generator №7 for its further use by the enterprise’s consumers.

In the process of overhaul, specialists will dismantle and repair gas pipelines, workplaces, shut-off rebar, etc. Currently, restoration of superheater structures, replacement of natural and blast furnace gas burners is underway. Also, the dismantling of the economizer pipes, which are also subject to restoration, continues.

«As a result of working in aggressive conditions with high pressure and temperature, the important technical units of the boiler unit have exhausted their operational resource, due to which the specific fuel consumption during the operation of the boiler was significantly overestimated. Therefore, it was decided to carry out a major overhaul of the unit, thereby guaranteeing its safe and economical operation,» the message says.

Estimated savings of natural gas after implementation of the planned repair measures will be 10%. The hourly productivity of the boiler unit will also increase.

After the overhaul is completed, commissioning tests will be carried out and appropriate operating modes of the equipment of boiler unit №11 will be established.

As GMK Center reported earlier, Kametstal carries out major repairs of turbogenerator №4 in the turbine shop of the heating plant. Among the main measures is the capital restoration of the generator, which involves complex repair intervention directly in the rotor nodes.