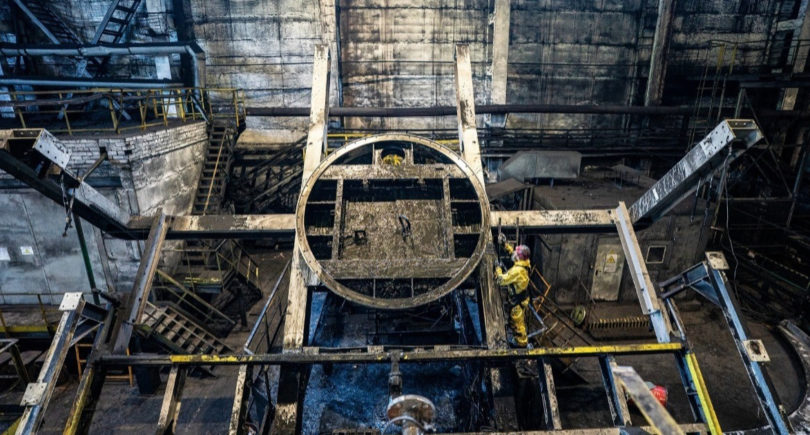

The main task was to restore the refractory lining of the air heater block

Kametstal Iron and Steel Works has carried out an overhaul of blast furnace No. 1M in an accelerated mode. This is stated in the company’s statement.

“Ensuring reliable operation of the main equipment to fulfill production tasks requires quick decisions and clear coordinated actions of the personnel. In the blast furnace shop of Kametstal, the overhaul of BF No. 1M was carried out almost in a pit stop mode,” the company noted.

The main task was to restore the refractory lining of the unit’s air heater block with the replacement of water-cooling elements of steel structures and hot blast valves. The efficiency of the blast furnace and the shop as a whole depends on the uninterrupted operation of this unit.

In addition, the upper and lower loading equipment and the bunker overpass were repaired. The key components of the castings opening and closing machines were repaired in the casting yard.

According to Yevgeny Podgorny, Deputy Head of the Blast Furnace Shop for Engineering, the team involved in the overhaul included contractors, specialists from Metinvest Promservice’s steel equipment repair shop and the shop’s repair services. Each employee was assigned specific hourly tasks by area.

“This made it possible to prepare the equipment complex of blast furnace No. 1M for further stable and reliable operation for the entire process interval until the next scheduled replacement of the furnace charging device,” noted Podgorny.

As GMK Center reported earlier, in September this year, Kametstal shut down BOF vessel No. 2 of the BOF Shop for a major overhaul as part of the 2024 overhaul program. The most important tasks include repair of the converter body and re-lining, with significant attention being paid to the power section.