News Global Market steel production 2305 05 February 2024

The initiative unites a consortium of nine partners from six European countries

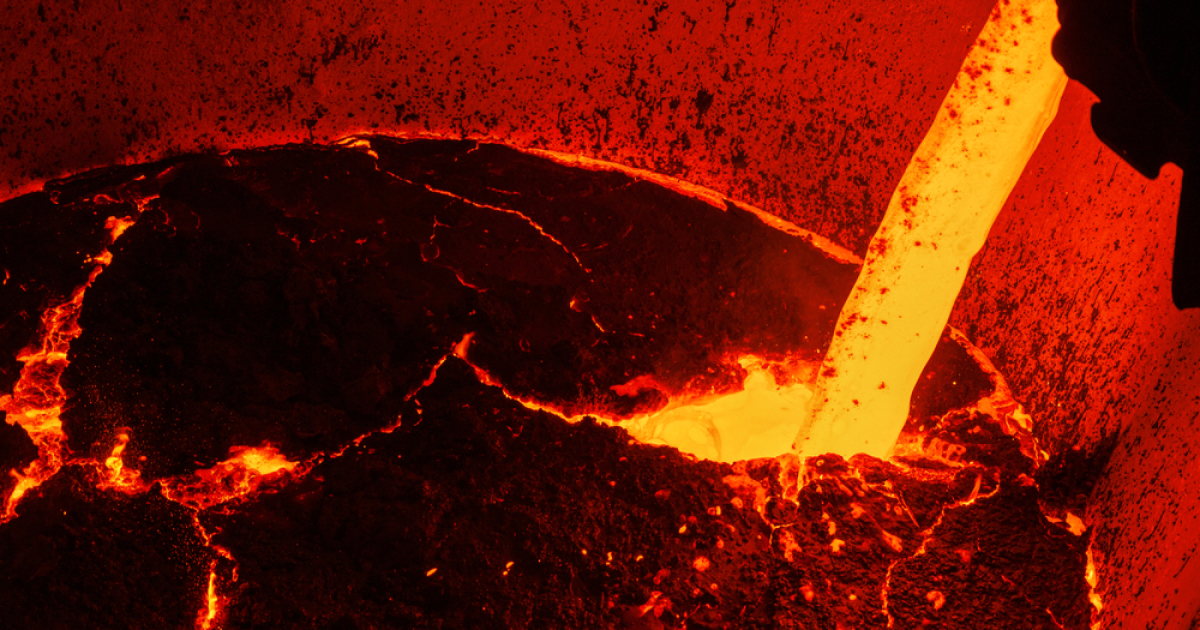

The EU has launched a new project, ZHyRON, which involves the introduction of a new process for processing steel by-products based on the use of green hydrogen. This is stated in the message of the Swedish manufacturer of steel structures and metal products GreenIron.

The project is funded by the European Health and Digital Agency (HaDEA) as part of the Clean Steel Partnership program. It brings together a consortium of nine partners from six European countries.

Funded by the EU, ZHyRON aims to pave the way for increasing the value of iron and zinc-rich steel by-products.

«The goal of the ZHyRON project is to transform the current linear steel production process into a circular and sustainable resource flow,» said Maciej Kaplan of Sweden’s GreenIron.

The project will explore solutions related to technical integration, economic viability and environmental considerations. This will contribute to the development of innovative business models and strategies for the extraction of iron and zinc from steel waste using hydrogen as a reducing agent.

From a technical point of view, the initiative’s approach involves a combination of pyro- and hydrosteel stages. The recovered iron oxides will be converted into direct reduced iron suitable for use in electric arc furnaces, while the extracted zinc will be processed into zinc oxide concentrate for use in a variety of sectors, from batteries to agriculture, as well as for wastewater treatment and reuse.

As GMK Center reported earlier, Thyssenkrupp Materials Services, a global distributor of materials and services, and CarbonChain, a UK-based software solutions provider, have announced a partnership. The companies will promote steel procurement with the help of a new carbon tracking tool.