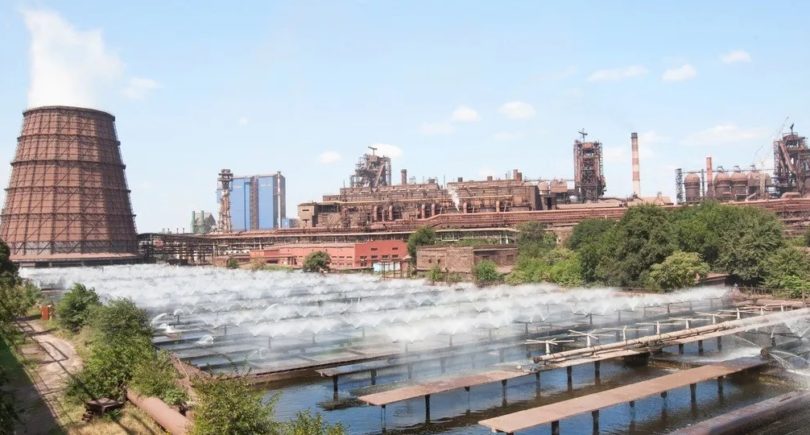

Ilyich Iron and Steel Works of Mariupol

Ilyich Iron and Steel Works of Mariupol is an integrated steel company. Sinter plant of Ilyich Iron and Steel Works of Mariupol is the largest in Europe. The company sells part of agglomerate to Azovstal Iron and Steel Works. Its main products are carbon flat products, low-alloyed and alloyed steels for various purposes. Heavy plates, produced by Ilyich Iron and Steel Works of Mariupol, are used in pipe production and shipbuilding; cold-rolled and galvanized plates — in cold forging and profiled sheeting production. The company also produces welded pipes for construction. Ilyich Iron and Steel Works of Mariupol is the largest European producer of cold-rolled and galvanized plates. Ilyich Iron and Steel Works of Mariupol leases the property complex of state-run Ukrmekhanobr to produce sinter ore. The company is part of Metinvest Holding.

Production capacity

Rolling mill 3000

Sheet rolling mill 4500

Cold rolling shop

Electric weld pipe shop

Pipe rolling shop

Staff and wages

Charts and tables

Production results, thousand tons

Indicative sales structure by products in 2020*

Indicative sales structure by countries in 2020*

* structure of sales volumes, metric tons

Financial performance, $ million

| 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|---|---|---|

| Sales | 2989 | 2389 | 1447 | 1394 | 2129 | 2908 | 3132 | 2862 |

| EBITDA | -188 | 230 | 37 | 110 | 100 | 291 | -94 | 220 |

| EBITDA margin | -6.3% | 9.6% | 2.6% | 7.9% | 4.7% | 10% | -3.0% | 7.7% |

| Net income | -366 | 38 | -73 | -6 | -31 | 122 | -209 | 7 |

| Net income margin | -12.3% | 1.6% | -5.0% | -0.4% | -1.5% | 4.19% | -6.7% | 0.2% |

| CAPEX | 59 | 28 | 27 | 61 | 133 | 187 | 142 | 216 |

Key facts

2021

Ilyich Iron and Steel Works completed overhaul of blast furnace No. 5 with $26 million CAPEX

2020

Ilyich Iron and Steel Works completed the reconstruction of the sinter plant with $160 million CAPEX

Ilyich Iron and Steel Works spent more than $30 million in the reconstruction of the mill “1700”

Ilyich Iron and Steel Works mastered 15 new types of products in 2020

2020

In the spring of 2020, Ilyich Iron and Steel Works started preparations for the construction of a new air separation unit. The capacity of the new equipment by Air Liquide will be 25 thousand cubic meters of gaseous oxygen per hour. The commissioning is scheduled for 2021.

Until the end of 2020, Ilyich Iron and Steel Works is going to reduce dust emissions by 90% due to the installation of gas cleaning systems at the sinter plant. CAPEX in the reconstruction of 12 sinter machines of the sinter plant of Ilyich Iron and Steel Works is estimated at $220 million.

2019

In November 2019, Ilyich Iron and Steel Works completed the reconstruction of the hot strip mill 1700. As a result, the HRC capacity increased to 2.5 million tons per annum. $114 million was invested in the project.

Metinvest Holding attracted €34 mln loan from Austrian bank ODDO BHF Aktiengesellschaft with guaranties of Austrian Oesterreichische Kontrollbank Aktiengesellschaft. The aim of the loan – reconstruction of the sheet rolling shop 1700 on Ilyich Iron and Steel Works of Mariupol.

Ilyich Iron and Steel Works of Mariupol and French company Air Liquide will build air separation plant with hourly capacity 25 ths m³ of oxygen. CAPEX to the project amounted $78 mln. As a result energy expenses will cut by 20%.

To 2020

Ilyich Iron and Steel Works of Mariupol will reconstruct the sinter plant to comply with the international environmental standards on emissions. Total investment in the project will amount to $220 million. By the end of 2020, dust emissions will decrease by 90% and sulfur by 43%.

In December 2018

Ilyich Iron and Steel Works put into operation the continuous casting machine No. 4. The project will increase production of semi-finished products by 30%, reduce the dust content in flue gases below European standards, and reduce raw materials costs. $150 million have been invested in the project.

In 2018

Ilyich Iron and Steel Works will invest $90 million in reconstruction of the sheet rolling shop 1700. The project includes installation of new equipment that will enhance the mill’s productivity, improve the quality of rolled surface, and reduce production waste during slab rolling. The project will enable the company to increase HRC maximum weight from 8 tons to 27 tons and thus to wide potential markets.

In 2016

Ukraine’s Ministry of Economy refused to extend the lease agreement between Ilyich Iron and Steel Works and the property complex of state-run Ukrmekhanobr. Ukrmekhanobr is a state-owned mining and processing plant, the property of which has been leased out to the company since 2006 and which has a special permit to mine the deposit. A trial was ongoing over the extension of the lease agreement in 2016–2018.

In 2015

Ilyich Iron and Steel Works fully put an open-hearth shop out of operation.

Data source for sections “Production results”, “Sales structure”, “Financial performance”: GMK Center calculations, based on companies`annual reports and web-sites data, media sources