News Companies зелена сталь 125 01 July 2025

The company has thus completed the full financing package for its project

Swedish steel company SAAB has announced that it has secured an additional €430 million in green financing to support its transformation project in Luleå, Sweden.

The latest financing was provided by the German export credit agency Euler Hermes. It complements the support previously provided by the Swedish National Debt Office (Riksgälden), the Italian export credit agency (SACE) and the Nordic Investment Bank (NIB). The transaction was structured by Crédit Agricole CIB.

“With this new green loan, we have completed the financial package needed to implement the transformation of Luleå,” said Lina Krelius, Chief Financial Officer at SSAB.

SSAB’s €4.5 billion investment in a new mini-mill in Luleå was announced in 2024. Four green loan facilities totaling €2.7 billion have been designed with long-term maturities that support the full life cycle of the project.

In total, the financing package includes:

- a syndicated loan of SEK 15 billion covered by the Swedish National Debt Office (Riksgälden) under the Credit Guarantees for Green Investments program,

- a syndicated loan of €808 million supported by SACE

- a loan of SEK 1.15 billion from NIB,

- a syndicated loan of €430 million supported by Euler Hermes Aktiengesellschaft.

Crédit Agricole CIB is the global coordinator, structural bank, and green loan coordinator for the financing package.

As noted, the Luleå transformation project involves the creation of a modern mini-mill that will play a central role in repositioning SSAB Europe as a premium product manufacturer while significantly reducing costs and carbon emissions.

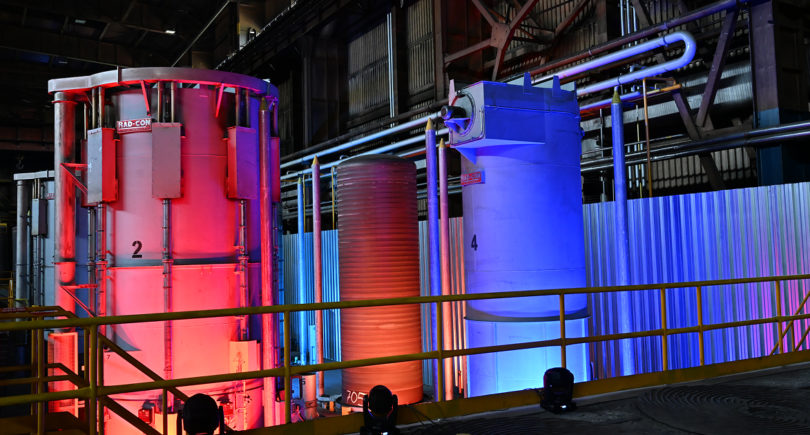

It should be noted that the new rolling mill with an annual capacity of 2.5 million tons will be equipped with two electric arc furnaces, a modern processing system, a hot rolling mill for the production of SSAB’s special products, and a cold rolling mill to serve car manufacturers. The company made the decision to build it in April last year.

Other advantages of the mini-mill include lower costs, shorter lead times, and better ability to manage fluctuations in demand.

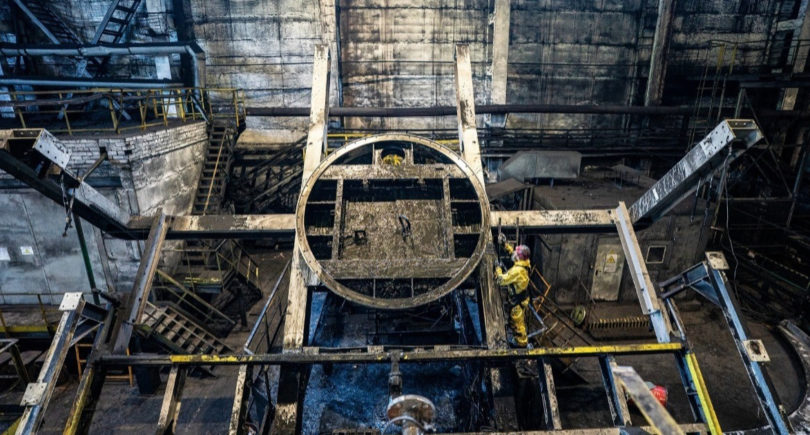

Once the new mill is completed, SSAB will close its current blast furnace-based production system in Luleå, which will significantly reduce carbon emissions from existing facilities.

In March this year, SSAB announced the installation of an electric arc furnace at its Ukselesund plant. This step is part of a major transformation of steel production aimed at reducing CO2 emissions. The new furnace is expected to be operational by the end of 2026, replacing traditional blast furnaces.