News Companies Salzgitter 2706 18 March 2024

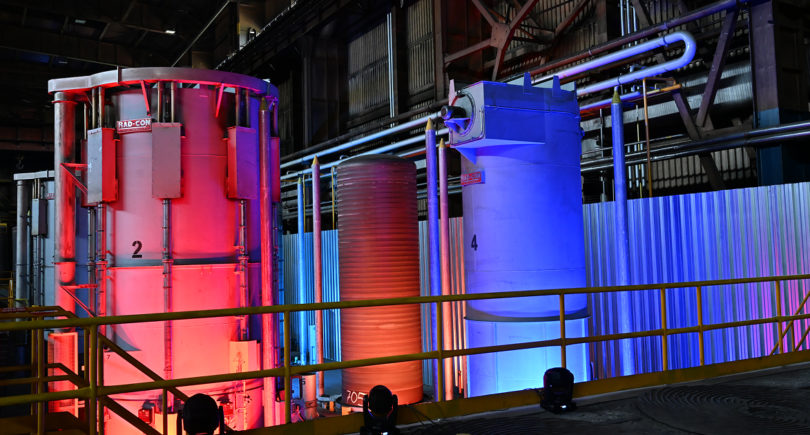

The new equipment will have a higher processing capacity and will be technically advanced

Salzgitter plans to invest €30 million in a new scrap shredder at its Salzgitter plant, Kallanish reports.

As Salzgitter CEO Gunnar Gröbler said during a press conference, the existing shredder at the plant does not meet the future requirements of the steelmaking process. The steelmaker has decided to modernize its scrap shredding capacity in preparation for steel production using more of this raw material, as part of its energy transition.

The new equipment will have a higher processing capacity and will be technically more advanced in separating impurities, producing cleaner scrap grades for further steelmaking, explained Gröbler.

The Salzgitter CEO also mentioned the acquisition of Must-Metal-Container-Recycling (Lower Saxony) in early 2023. This way, the company is strengthening its scrap resources. In addition, this step is a further development of local sources of raw materials located near the Salzgitter steel plant.

Last fall, Italian Arvedi put a new scrap shredder into operation at its Acciaieria Arvedi plant in Cremona. The unit was developed by Danieli Centro Recycling. The equipment is designed to process small and medium-sized scrap. Its capacity reaches 1 million tons per year. The new shredder will produce high-quality, high-density feedstock for feeding into the company’s electric arc furnaces.

As GMK Center reported earlier, in 2023, Germany reduced its exports of ferrous scrap by 3% compared to 2022 – to 7.61 million tons, the lowest volume since the 2009 crisis. The total value of raw material exports last year amounted to €4.1 billion (€4.9 billion in 2022).