News Companies Central GOK 2221 29 March 2024

Specialists updated the units in 14 days

Metinvest Group’s Central Mining and Processing Plant (Central Mining) has completed a major overhaul of the OK-324 roasting machine at its pelletizing plant. This is stated in a press release by Metinvest.Media.

The equipment at the pelletizing plant operates continuously, around the clock, for more than 7.5 thousand hours a year, so miners pay a lot of attention to its technical condition. The specialists upgraded the equipment in 14 days. The repairs were carried out as part of the pellet production process optimization program.

«One of the key areas was the restoration of the refractory masonry of the roasting machine furnace and the repair of six nozzles. This step is crucial to preserve the thermal insulation of the roasting furnace’s hearth space and will help avoid the destruction of the brickwork and ensure continuous operation of the plant during the overhaul period,» said Andrey Ivanov, Deputy Head of the Pelletizing Plant at Central Mining.

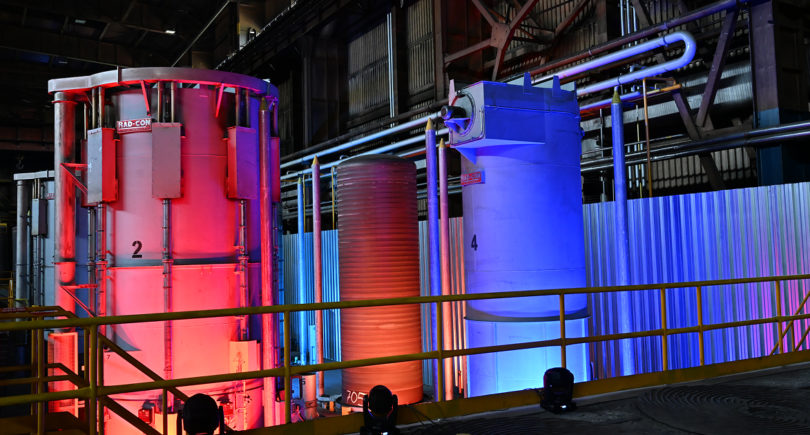

During the repair, an experimental solution was also implemented to apply shotcrete to the surface of the No. 9 and No. 10 tanks. This can significantly increase the durability of refractory insulation by reducing the impact of biofuels.

Additionally, the specialists repaired the drip traps of smoke exhausters D2 and D5 and completely replaced three sections of drip trap No. 2 of smoke exhausters D2. This will help to reduce emissions and improve the gas dynamics of the heat flow. This operational improvement will significantly reduce the time of equipment operation during the shutdown of the plant for scheduled repairs. The installed mechanism will help reduce energy consumption and improve equipment reliability.

As part of the overhaul, the plant also carried out maintenance of the conveyor transport, including the replacement of rollers, seals and lining of the reloading units.

As GMK Center reported earlier, Central Mining carried out a scheduled overhaul of the 140-ton 3.6 x 5.0 mill at the ore dressing plant. The quality of concentrate production depends on the efficient and trouble-free operation of the equipment.