News Companies ArcelorMittal 1629 11 August 2023

Investments in the reconstruction of the unit amounted to more than 720 million zlotys

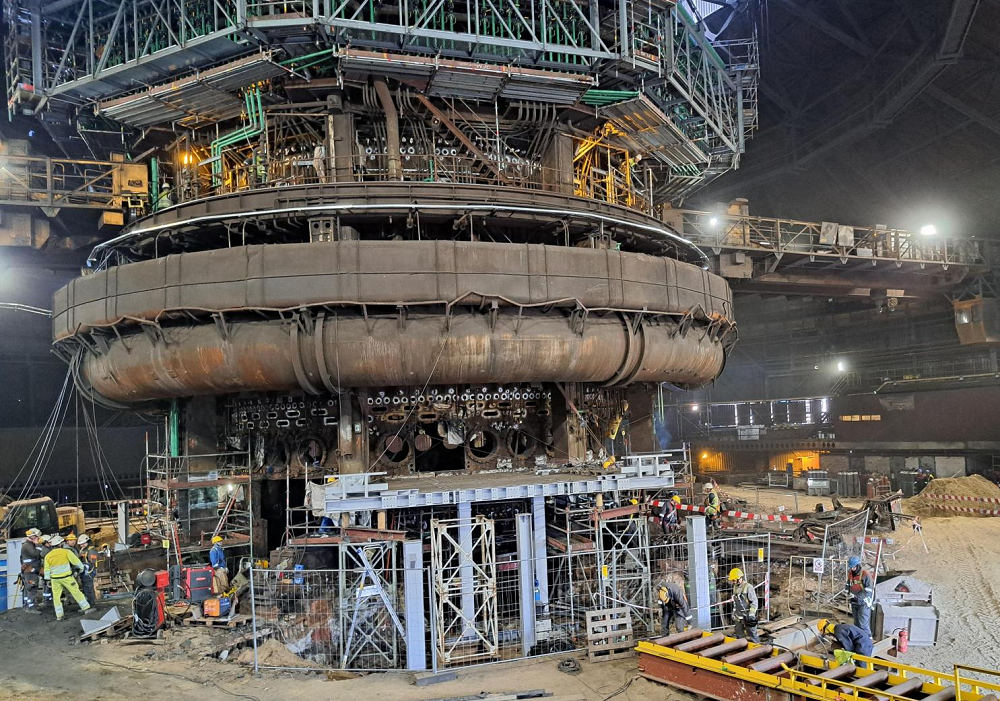

ArcelorMittal Poland completed the reconstruction of blast furnace (BF) №2 at the plant in Dąbrowa Górnicza – it has been ongoing since the end of March 2023. Investments in modernization amounted to more than 720 million zlotys ($167 million). It is stated in the company’s message.

The renovation included, among other things, the construction of a new cooling system and a modern blast furnace gas cleaning facility.

According to Michal Kotsot, head of the overhaul of BF №2, in addition to standard works, the dust collection plant of the foundry was also thoroughly modernized, a new blast furnace loading system was built and nozzle sets were modified, and a new automation and process control system was installed.

«Implemented technical solutions have once again increased the level of technological safety of our installations,» noted Radoslav Dzedzich, head of the blast furnace shop of ArcelorMittal Poland in Dąbrowa Górnicza.

Thanks to the construction of a new BF cooling system and the installation of heat exchangers, the company increased the efficiency of the process and reduced the addition of water to the cooling circuit of the nozzle sets by 85%. The modernization will also reduce electricity consumption by almost 400 MWh per year and reduce carbon emissions by approximately 45,000 tons per year.

Start-up tests of individual elements of the installation began in the second half of July, the blast furnace was blown at the beginning of August. Almost 50 third-party companies participated in the project to modernize the state-owned enterprise. The repair extended the service life of the unit for the next 15 years.

As GMK Center reported earlier, ArcelorMittal Poland invests in modernization of coking plant in the city of Zdzešowice 165 million zlotys ($38.5 million). The modernization includes the installation of three flue gas denitrification units for the cogeneration plant (CHP), which will significantly reduce nitrogen oxide emissions. In addition, a project on the reconstruction of the balancing tank of coke gas will start on the territory of the plant. It will replace an existing twin installation that is in need of rehabilitation.