News Companies capital investment 933 30 July 2022

The unit is located in a mine with a depth of 1 thousand meters and is designed to operate a lifting machine that delivers rock to the surface

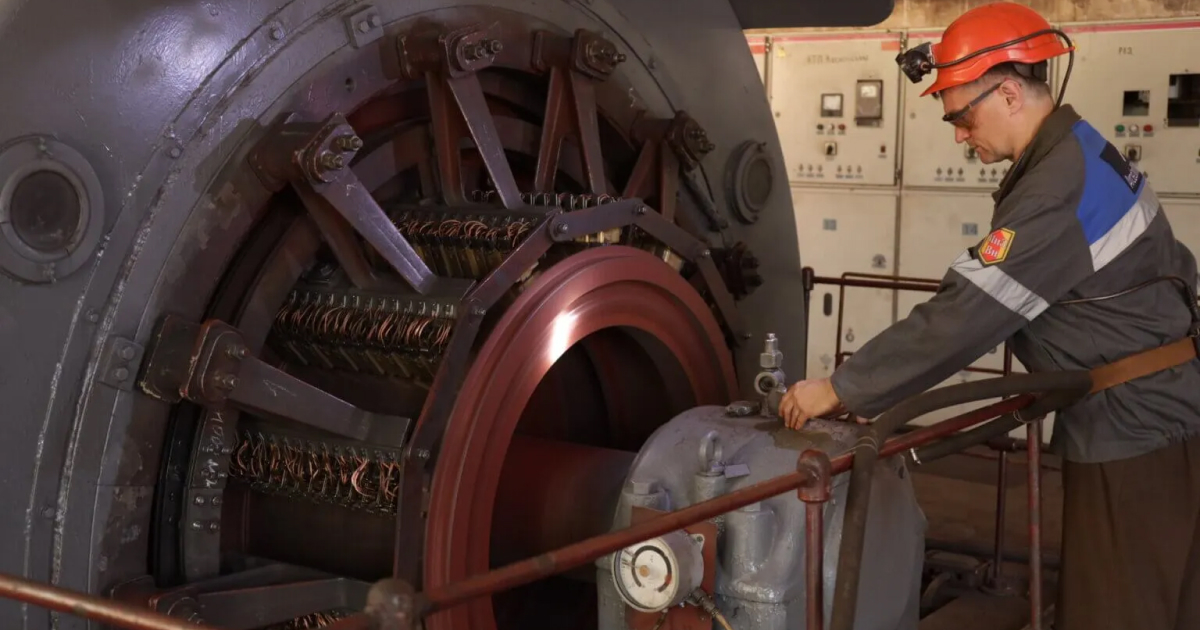

ArcelorMittal Kryvyi Rih during the shutdown of the steel processing stage performed a major overhaul of the generator GP-4000 of the skip hoist. This is stated in the press release of newspaper Metallurg.

The equipment is located in a mine at a depth of 1,000 meters, and it was possible to repair it when production was completely stopped.

The generator is part of the skip hoist electric drive. The plant itself is one of the most important sections in the chain of “mining-issuance-transportation” of iron ore, quartzite and waste rock for further production of sinter ore. The generator is part of the “generator-motor” group.

“The generator provides power to the drive engine, which wraps the drum of the skip machine, and with its help, the rock is brought to the surface. There is no other way to release iron ore from the mine. To buy a new unit, we need more than one million hryvnias, and the overhaul allowed us not only to save money, but also extended the life of important mining equipment,” said Kostyantyn Shepelev, chief engineer.

Specialists replaced the main components of the unit, repaired bearings and auxiliary drives. In addition, at the level of 1.105 thousand meters, the apron feeder was replaced, which is involved in the ore delivery chain by conveyor transport to the batcher. Steel structures were also replaced – support beams, feeder beams and maintenance platforms.

As GMK Center reported earlier, ArcelorMittal has been suspended work of mining and processing plant for the next three months. Employees of the Mining Department will be paid 2/3 of their salary.

Prior to this, the plant transferred a significant part employees, including top management and foreign workers, by 2/3 of the load due to the inability to pay salaries in full.