The company outlined a decarbonization strategy for the near term

ArcelorMittal Nippon Steel India (AMNS India), a joint venture between two of the world’s leading steelmakers, plans to reduce its emissions intensity by 20% by 2030 across its value chain. This is stated in the relevant climate action report released by AMNS.

«Research shows that without a transformation of steel production, growing demand could lead to a 200% increase in emissions from the sector by 2050. Today, we are announcing that we aim to reduce AMNS India’s emissions intensity by a further 20% and have developed a roadmap to achieve zero emissions in the long term,» said Aditya Mittal, Chairman of the Board of AMNS.

According to him, the company currently has one of the lowest emissions intensity indicators among integrated steel producers in India, having reduced it by a third since 2015.

The strategy outlines AMNS’ near-term plans to decarbonize while driving the company’s growth.

It includes improving operational efficiency through technological improvements. It also envisages increasing the use of renewable energy sources. The company aims to provide a 100% green network by 2030.

According to the report, ArcelorMittal has invested $0.7 billion in new solar and wind power plants that will be integrated with pumped storage plants owned by Greenko to supply electricity to the Khazira plant around the clock. By the end of 2024, they will meet more than 20% of the plant’s electricity needs, which will help reduce carbon emissions by 1.5 million tons annually.

By 2030, AMNS also intends to increase its scrap utilization rate from 3-5% to about 10%. In addition, it plans to set up several scrap recycling centers across the country to encourage a circular economy of steel production in India.

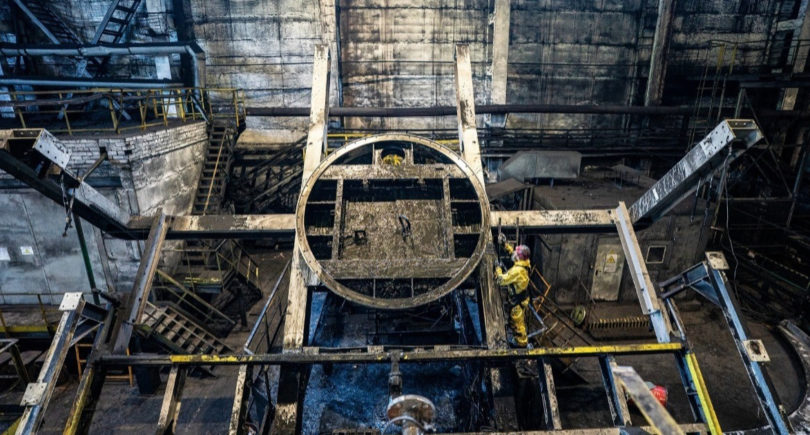

In parallel with these measures, the company is focused on designing the next phase of its blast furnace steel plants so that they have the space and capabilities to rapidly adopt low-carbon processes such as hydrogen-based production.

Strategic investments are also being made in pilot projects and partnerships in disruptive technologies such as green hydrogen and carbon capture, use and storage (CCUS).

AMNS has a steelmaking capacity of 9 million tons per year, produces a fully diversified range of flat products, including value-added steel, and has pellet production capacity of 20 million tons.

As GMK Center reported earlier, AMNS India is building the world’s largest standalone integrated steel plant in Hazira, Gujarat. The plant will have a capacity to produce 24 million tons of steel per year and is expected to be completed by 2029.