News Companies decarbonization 2718 29 March 2024

The new enterprise aims to scale solutions for the production of such products

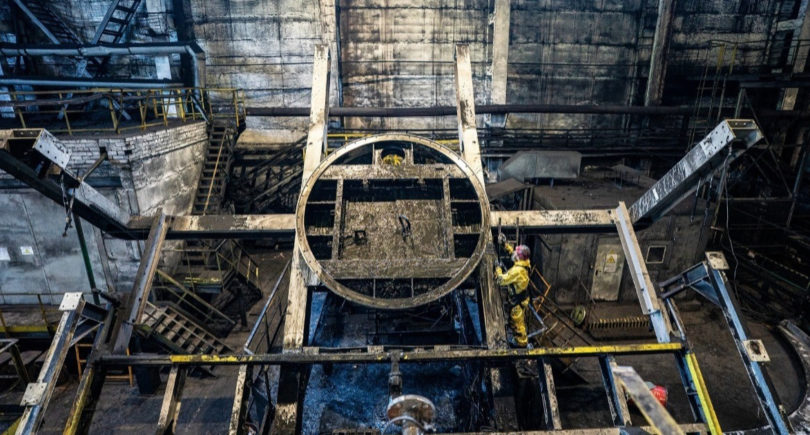

US-based Electra has announced the commissioning of a pilot plant in Boulder, Colorado, USA, to produce pure iron, BusinessWire reports.

The plant will use Electra’s technology to produce iron from already mined, commercially available high-grade ores to accelerate decarbonization and circularity throughout the steel value chain from raw materials to steel.

The pilot project is designed to produce pure iron in the form of plates measuring approximately 1 square meter, and the company is increasing capacity in stages to validate the modular approach.

Electra’s unique, patented electrochemical system converts iron ore into iron through an electrochemical process at 140°F. It is powered by clean, renewable intermittent renewable energy sources (IRES).

«With support from our partners across the value chain, the Pilot brings us closer to our goal of producing millions of tonnes of clean iron by the end of the decade,» said Sandeep Nijhawan, CEO and co-founder of Electra.

Electra’s products, with a purity of more than 99%, combined with recycled scrap, provide customer value to electric arc furnace steelmakers, reducing capital intensity, cost, and waste throughout the value chain.

Australian mining company BHP, an investor in Electra, provided the iron ore for this pilot project.

Electra’s CTO and co-founder Kwok Pham noted that they are moving forward quickly, with the commissioning of the pilot plant taking place within 3.5 years of the company’s founding.

As GMK Center reported earlier, US Steel has completed a pilot project in Minnesota to produce DR pellets. In 2024, the company intends to improve the operational practices of this production and ship products in the first half of the year.