The modernized unit will ensure a stable technological process and reduce energy costs

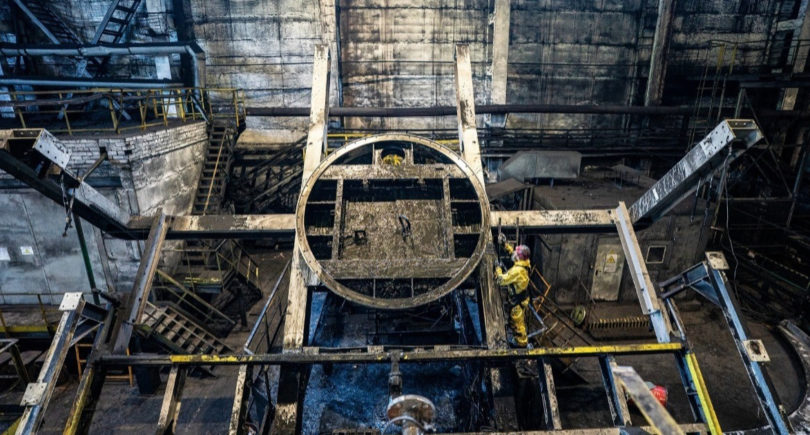

After a major overhaul, Kametstalhas put into operation a fire heating furnace for the recovery oil in the coking chemicals recovery shop. The equipment upgrade is aimed at stabilizing the technological process and reducing the company’s energy costs, according to a press release.

The furnace performs a key function in the production of crude benzene by heating the absorbent oil to a temperature of 135-160°C before it is fed to the benzene column. Coke oven gas is used as a heat source, which significantly reduces the cost of expensive steam.

During the repair, the company’s specialists replaced the tubular coil and bends with new ones made of heat-resistant steel. This solution made it possible to utilize all heating surfaces and significantly increase the efficiency of the unit. The heating system was also upgraded: the coke oven gas burners were completely replaced, new shut-off valves were installed, and the gate control system for gas outlet control was restored.

Special attention was paid to labor safety. The furnace service areas were restored, ensuring their reliability and integrity. The furnace bottom was sealed to prevent combustion product leaks.

As GMK Center reported earlier, Kametstal has completed a major overhaul of medium-pressure boiler unit No. 6, which has a capacity of 90 tons of steam per hour. The refurbishment of the equipment will help to ensure stable steam supply to the plant and increase the efficiency of the unit.

In 2025, the company plans to invest UAH 2.5 billion in the modernization of its production facilities, a record amount of funds in recent years. Key projects include the overhaul of blast furnace No. 9 and the construction of a solar power plant.