The updated equipment will help avoid emergency stops and unscheduled downtime

As part of its scheduled overhaul, Kametstal has upgraded Ladle Furnace No. 1 (LF-1), which plays a key role in the out-of-unit steel finishing process. The work was focused on improving equipment reliability and preventing emergency shutdowns in the future, according to a press release from the company.

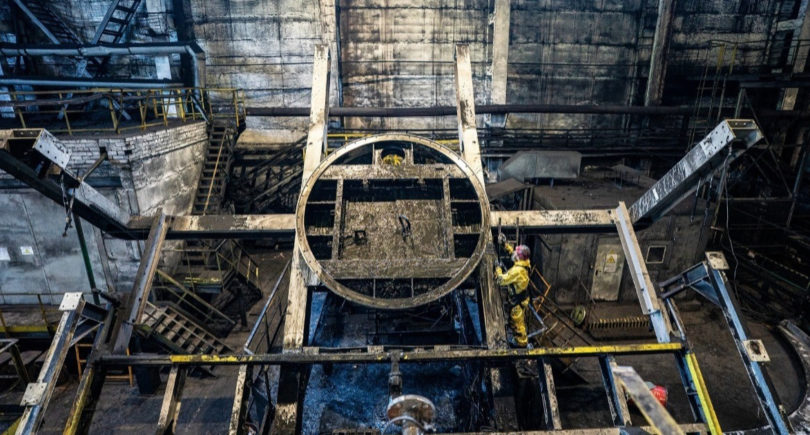

The centerpiece of the repair was the replacement of the water-cooled vault, an important component that prevents secondary oxidation of the metal and emissions of slag or steel from the ladle. It is the efficiency of this part of the plant that determines the stability of the temperature regime and the quality of the processed steel.

According to Yevgeniy Tkatsevich, Senior Foreman of the Out-of-Aggregate Finishing Shop, after dismantling and defecting, an optimization decision was made not to buy a new vault but to restore the existing one. Thanks to the coordinated work of the metallurgical equipment repair specialists and technical services of the shop, the damaged elements were completely replaced, and the unit was assembled, centered, connected to power and tested.

At the same time, infrastructure repairs were carried out, which are only possible during the shutdown of CCM-1: the steel carrier was replaced, a 35 kW transformer was inspected, the cooling reactor was upgraded and a new vacuum chamber was installed.

After the repairs were completed, CCM-1 was successfully put into operation and operates steadily, alternating with CCM-2, ensuring production continuity and compliance with quality standards.

As GMK Center previously reported, Kametstal has started overhauling one of the key units of its steelmaking operations, BOF vessel No. 1. The work is being carried out as part of the 2025 overhaul program with a focus on upgrading the main equipment and power systems.