News Companies Dnipro Metallurgical Plant 1814 07 April 2024

The next important unit to be manufactured by the plant's specialists will be a three-story mine cage

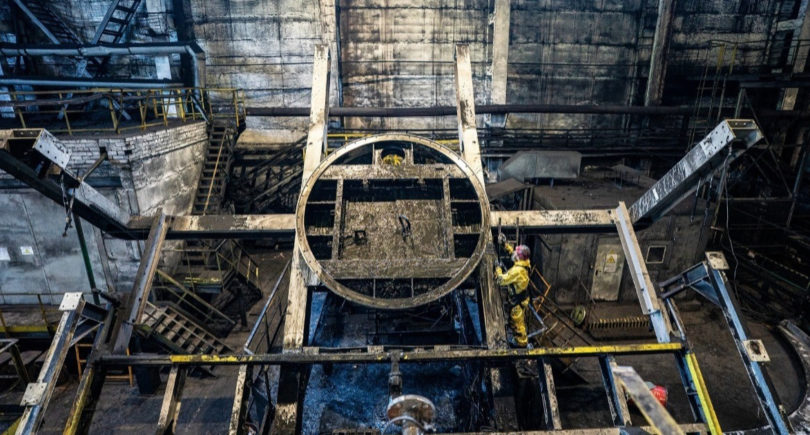

Dnipro Metallurgical Plant (DMZ), part of DCH Steel, has produced an important and unique unit for the Sukha Balka mine for the first time – a mine skip. This is stated in the company’s corporate newspaper.

«Permission to produce it was obtained from representatives of the State Labor Service who visited the plant to test the capabilities of DMZ’s repair units,» the statement said.

First, the model shop of the molding and casting department of the specialized steel equipment repair shop (SSERS) made models according to the provided drawings. They were sent to the casting department, where some parts of the skip were cast. After machining, they were moved to the repair and manufacturing area for auxiliary equipment for further assembly.

When the company received additional materials and components, DMZ employees produced other steel structures necessary for the skip. The assembly process continued for several months.

«The task was not an easy one, it required skill and attention to detail, especially at the stage of working with drawings and assembling metal structures,» said Oleksandr Vylyvanyi, chief mechanic at DMZ.

When the skip was assembled, representatives of the mine came to the plant. They carefully checked the work of the partners and approved it.

This hoisting mechanism is unique because there are no other mining skips of this size in the world with a volume of 25 cubic meters and a lifting capacity of 53 tons from a depth of -1500 meters. Usually, miners use smaller units of 20 cubic meters.

The skip was transported to the mine, where it was covered with an anti-corrosion coating, including galvanizing and painting. It was lined with lining made in Sweden. The skip is currently being installed at Yuvileyna mine.

The next important unit to be manufactured by the plant’s specialists will be a three-storey mine cage.

As GMK Center reported earlier, Sukha Balka plans to increase its commercial iron ore production by 20% in 2024 compared to 2023, to 1.134 million tons. In 2023, the company mined 1.082 million tons of raw ore, 941 thousand tons of commercial ore, and 12.918 thousand cubic meters of rock mass. The company completed 7,942 thousand meters of sinking operations and 140 km of deep wells. In 2023, Sukha Balka shipped 98% of its products for export.