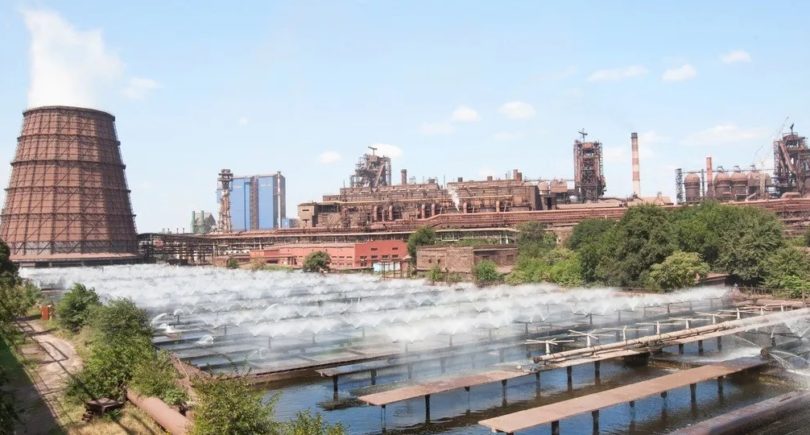

Azovstal Iron and Steel Works

Azovstal Iron and Steel Works is an integrated company, a subsidiary of Metinvest Holding. It produces flat and long products, rolled sections and has coke production facilities. Azovstal specializes in semi-finished products, processed by Metinvest Holding’s European subsidiaries, as well as plate products, sold in the EU and the Middle East markets. Azovstal’s plate products are used in shipbuilding, power and special engineering, bridge construction, and production of large diameter pipes for gas and oil pipelines. Azovstal Iron and Steel Works is the only rail manufacturer in Ukraine. The company closely cooperates with another subsidiary of Metinvest Holding located nearby — Ilyich Iron and Steel Works of Mariupol that supplies iron ore agglomerate.

Production capacity

2 twin ladle furnaces

Twin vacuum degasser

4 double-strand CCMs

Plate mill: plate mill 3600

Rail and structural mill: rail and structural mill 1000/800

Heavy section mill: heavy section mill 800/650

Rail fasteners mill

Ball rolling department: grinding balls diameter 40–120 mm

Staff and wages

* per worker before taxes

Charts and tables

Production results, thousand tons

Indicative sales structure by products in 2020*

Indicative sales structure by countries in 2020*

* structure of sales volumes, metric tons

Financial performance, $ million

| 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

|---|---|---|---|---|---|---|---|---|

| Sales | 2610 | 1882 | 1212 | 1277 | 2593 | 3013 | 2217 | 1875 |

| EBITDA | -83 | 182 | 2 | 126 | 113 | 277 | -127 | 168 |

| EBITDA margin | -3.17% | 9.71% | 0.19% | 9.87% | 4.36% | 9.2% | -5.7% | 8.9% |

| Net income | 2.51 | 0.92 | -1.84 | 0.56 | -0.13 | 131 | -219 | 16 |

| Net income margin | 12.03% | 4.09% | -6.95% | 1.71% | -0.19% | 4.36% | -9.9% | 0.8% |

| CAPEX | 136 | 110 | 50 | 58 | 103 | 166 | 184 | 118 |

Key facts

2021

Azovstal has reconstructed gas cleaning systems of converters №1 and №2

Azovstal received a certificate for ship steel from the US classifier

Azovstal saves more than $100 million per year due to operational improvements

2020

Azovstal mastered 20 new types of products in 2020

2020

In June 2020, Azovstal Iron and Steel Works invested over $9 million to replace the second mixer in the BOF shop.

In May 2020, Azovstal stopped the blast furnace No. 4 due to a falling demand in global markets. During downtime, the furnace was overhauled.

2019

In 2019, Azovstal reduced gross emissions of pollutants into the air per ton of steel by 7.0% to 20.2 tons. This was possible due to environmental projects: the overhaul of the blast furnace No. 3, reconstruction of the aspiration system of the crushing shop, reconstruction of the gas cleaning system of the pig iron desulfurization shop.

In June 2019, Azovstal completed the overhaul of the blast furnace No. 3. The overhaul of the blast furnace No. 6 project was launched.

In 2019, Azovstal launched 32 new types of metal products.

Azovstal stopped blast furnace #6 for rebuilding works. The project intends energy efficiency improvements and cost decreasing. Blast furnace #6 will be equipped with a pulverized coal injection (PCI) unit and slag granulation plant. As a result, dust emissions will reduce by 55%.

Azovstal stopped blast furnace #5. It will be decommissioned and dismantled.

In the end of June 2019

Azovstal plans to launch the repaired blast furnace 3. As a result, the furnace will be equipped with a pulverized coal injection (PCI) unit, and its capacity will be increased to 1.3–1.6 million tons. CAPEX into the project – $145 mln.

In January 2019

Azovstal launched new products, slabs 300 mm for industrial consumers in the EU and the Middle East. One of the CCMs was reequipped for that purpose.

In May 2018

Metinvest Holding management said they planned to invest $6 billion in steel assets, including $300 million for environmental measures.

In 2018

The company invested UAH 0.5 billion in the upgrade of the environmental safety and cooling system of the blast furnace 4.

In 2017

Azovstal invested $90 million in the reconstruction of the blast furnace 4. As a result, its productivity enhanced by 20%. The furnace was also equipped with a PCI unit. Therefore, the blast furnace 4 became the most environmentally friendly in Ukraine.

Data source for sections “Production results”, “Sales structure”, “Financial performance”: GMK Center calculations, based on companies`annual reports and web-sites data, media sources