News Companies Thyssenkrupp 341 07 July 2025

Upgraded facilities will deliver higher quality steel for automotive manufacturing and energy transition

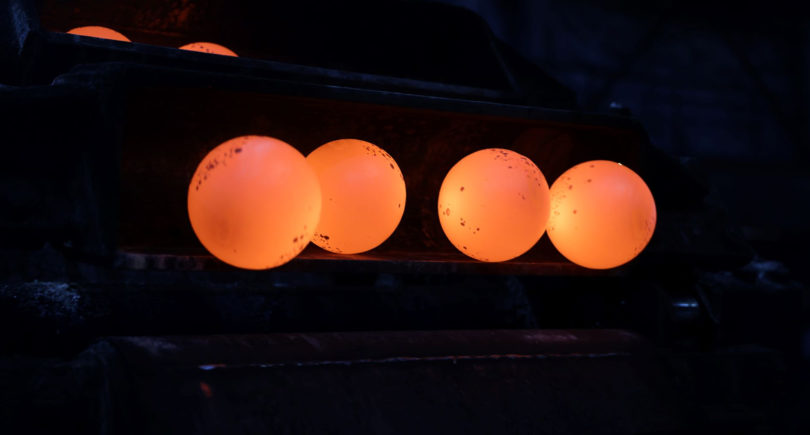

Steel company thyssenkrupp Steel Europe has completed a major upgrade of its production complex in Duisburg, Germany. After two years of construction and installation, the company has launched a new continuous casting machine (CCM) No. 4, a deeply modernized hot rolling mill No. 4 with two walking beam furnaces, and fully automated slab logistics. This is stated in the company’s press release.

The €800 million investment is one of the largest in the company’s history and is aimed at improving product quality, increasing efficiency, and expanding supply flexibility.

The new facilities enable thyssenkrupp Steel to produce thinner and stronger steel grades, particularly for the electric vehicle industry and energy transition projects. The continuous casting machine ensures high purity, shape accuracy, and improved surface quality of slabs. The upgraded rolling mill is designed for 3 million tons of steel per year and is equipped with the latest thickness control, cooling, and processing systems, enabling the production of dynamo and transformer steels.

Automated slab logistics between the two divisions allows up to 1.7 million tons of material to be processed annually in real time, significantly increasing the overall efficiency of the production network.

According to management, the investment is a strategic step towards strengthening the company’s technological leadership and ensuring stable operations in a changing economy. The new facilities lay the foundation for expanding the product portfolio and ensuring sustainable production development.

«This project is a decisive milestone in strengthening our leadership in technological and quality terms, while meeting the increasing expectations of our customers. Despite a very challenging economic environment, we are able to invest around 800 million euros to further improve our competitive position. This is a strong signal for steel and the Duisburg location. The future is being created here,» comments Dennis Grimm, CEO of thyssenkrupp Steel.

As a reminder, the industrial group Thyssenkrupp has announced plans to transform itself into a holding company with controlling stakes in individual business segments. The future strategic target model will be presented to the supervisory board by the end of the current financial year. It is noted that the basis of the plans is the gradual separation of all business segments and their opening to third-party investments.