News Global Market hydrogen steel industry 3769 28 June 2024

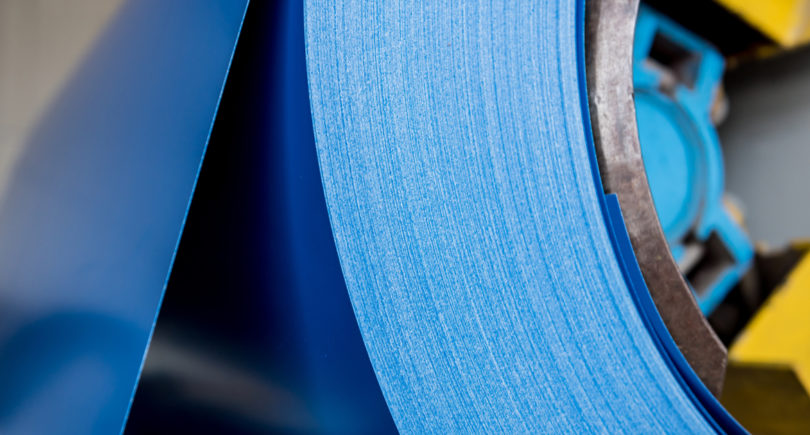

HyREX hydrogen reduction process is used in production

South Korea’s largest steelmaker, POSCO, has unveiled a pilot steelmaking plant that runs on hydrogen rather than fossil fuels. This is reported by KED Global.

In this way, the South Korean company is moving towards its carbon neutrality ambitions.

The pilot plant at the Pohang facility has a production capacity of 24 tons of molten iron per day, emitting 400 kg of carbon per ton, which is significantly lower than at existing fossil fuel-based steel mills. The company expects the facility to become carbon-free after the transition to renewable energy.

The production process uses the HyREX hydrogen reduction process.

«Carbon neutrality is not an obstacle, but an opportunity for the steel sector,» said POSCO Senior Vice President Bae Jin-Chang, who is in charge of the project.

In April 2024, the company succeeded in producing molten iron at the HyREX pilot plant, which was then undergoing repairs to improve post-process quality and develop additional technologies. Initial analysis showed that post-process quality, such as carbon specific gravity, did not meet POSCO’s standards.

Posco plans to start construction of the full-scale HyREX steel plant with a production capacity of 36 tons of iron per hour in early 2025, with completion scheduled for 2027.

The company intends to produce 2.5 million tons of steel per year using this process by 2040, and to switch to hydrogen-based production by 2050.

Earlier this year, POSCO began construction of a 2.5 million tonne per annum electric arc furnace at its Gwangyang plant. It is planned to be completed by the end of 2025, and the official operation of the EAF will begin in 2026. When the planned production volume is achieved, the company will be able to reduce carbon emissions by about 3.5 million tons per year compared to blast furnace production.