News Companies ArcelorMittal 2280 17 June 2024

The company opened a new line for the production of welded billets for the automotive industry

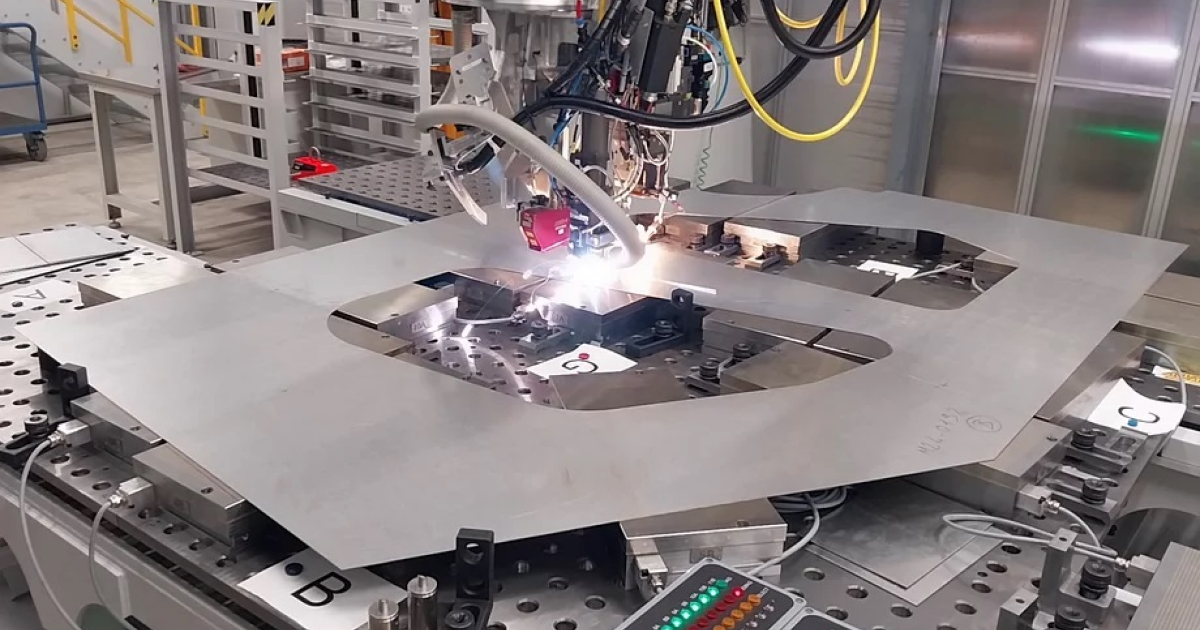

Global steelmaker ArcelorMittal is expanding the capabilities of its Montataire research center (France). In June of this year, a new ArcelorMittal Multi Part Integration (MPI) line was opened here, the company said in a statement.

The laser ablation and welding line is designed to test various production processes and shapes of welded blanks, as well as to produce prototypes for ArcelorMittal Tailored Blanks, a company specializing in the production of welded blanks for the automotive industry.

MPI is a concept that combines numerous stamped parts into a single laser welded blank (LWB), reducing the complexity of the structure. The line uses the latest hot forming steels (PHS), LWB hot forming technology and patches if necessary.

For automakers, MPI simplifies vehicle production by reducing the number of processes, the required production space, shortens assembly time, reduces vehicle weight using new generation steel grades, and helps reduce carbon emissions and costs.

The new line includes 10 advanced technologies that will enable the development of new laser welding processes for large billets (up to 4×2.5 m) and the production of demonstration samples to convince automakers of the technical feasibility of innovative concepts.

ArcelorMittal, Japan’s Mitsubishi Heavy Industries and partners have announced that they have started operating a pilot carbon capture unit at a blast furnace at ArcelorMittal’s steel plant in Ghent, Belgium. The pilot plant will operate for 1-2 years to test the feasibility of a full-scale deployment of the technology, which, if successful, could capture a significant portion of the plant’s emissions.